Contents

It is no mystery that having qualified equipment in your company optimizes business productivity and improves your operational context. The fact is, to guarantee proper use of devices, you need to do an equipment criticality analysis in order to prioritize maintenance actions.

In a company, different managers can have different opinions about equipment criticality, therefore it is important to have data on hand for making better decisions.

This attitude allows the productive system to function as close to its capacity as possible. After all, by defining which equipment are in critical situations, it is possible to identify how indispensable it is, creating efficient maintenance strategies.

So how to make a good analysis and reap the fruits of an attitude that only brings benefits to your company? To answer this question, we developed this article with the main information about equipment criticality. Have a good reading!

What is equipment criticality?

Do you know how much each equipment in your industry can impact your production process?

Before you even know how to do the analysis, it’s critical to understand your concept. Well, the equipment criticality is an indicator that will inform the risk that an equipment shows for your company, making maintenance easier.

It is impossible to have a good productivity, even more growing, when there is no organization of all processes.

In this sense, it classifies the effects and risks that dysfunctional equipment can cause, based on the risk studies, the project reliability, as well as the importance of the equipment and its operation plants. Because of that, it is possible to determine which equipment has most impact in the business potential, optimizing to achieve the organization goals.

It is worth remembering that the analysis is conducted from two methods: quantitative and qualitative. While the first it is about getting critical and reliable numbers based on failure rates, the second refers to the criticality classification in a subjective way from the staff tacit knowledge, given that there is not numeric data to assist the analysis.

Developed in 1950s, the FMEA was one of the first methods organized to criticality improvement. After almost seven decades, it is still an effective method to reduce failures in a production cycle.

The analysis of failures methods and effects offers benefits, between them, the costs reduction. Therefore, the expenses with failures prevention will become lower than that used by the repair ways when the problem appears.

Every kind is based on the operational scheme approved by the documents MIL-STD-1629 and IEC 60812, to guarantee real rates and, of course, to provide effective strategy that will enhance the business results.

What is the importance of equipment criticality?

You may have already noticed that the main function of the equipment criticality analysis is to identify which equipment needs the first repair in maintenance, corrective or not. In a first moment, this optimizes the time and the available resources to realize with perfection, since both are limited.

This allows to create a maintenance plan consistent with the business needs, lining up the planned and control of this process with the equipment criticality and the impact that it has on your business. Therefore, while you increase staff productivity, you also optimize target achievements and occupational goals.

Considering that the relation between the organizational performance and the equipment failure directly affects in the decision making about where to apply the resources, when identifying which items need to be prioritized, you optimize time and money, in addition to improving the equipment reliability.

To sum up, all analysis process also brings to discussion about worker health, ensuring that safety is put first, returning the reliability that was lost. This encourages the employees to develop a better work, increasing the organization’s productivity.

What is the criticality level?

In the face of all these benefits, it is common to think in the equipment analysis possibilities, isn’t it? The fact is that there are a lot of ways to establish if an equipment is working correct or not, it has the purpose to automate the analysis process to create less strategies based on feeling.

The criticality is measured by legit and proven methods, even if the analysis has been made from qualitative techniques. One of the most used methods is ABC classification, that is responsible for determining a criticality level through questions and answers about the equipment.

So, it is based on five assessments process on three different levels – safety, reliability, quality, frequency, and cost. Each one is used to rate the equipment in the following classifications: A (maximum criticality), B (moderate criticality) or C (minimum criticality).

In this case, a flowchart is used to identify each assessment and level, establishing the classification where the device is placed. To maximize the process, you can establish during maintenance the cross-functional relationship, between equipment and its use, risks derived from the potential for failure and environmental policies that embrace your asset.

What are the criticality types?

To exemplify, we have available an equipment criticality spreadsheet, there you will answer the items according to criticality level A, B and C. Based on Japan Institute of Plant Maintenance (1995):

Level A: Highly critical equipment to the process, being essential a preventive action: predictive or preventive, maintenance and operation failures analysis, centered staff improvement, centered staff in failures reductions, application of RCM or FMECA.

Level B: Equipment important to the process, acceptable application of any of the following actions: preventive and predictive, improvement staff, maintenance failures analysis.

Level C: Lower impact equipment to the process, with the following actions: corrective, predictive and/or preventive maintenance, monitoring failures to avoid recurrent.

After analyzing and qualifying each step, the equipment criticality will be raised.

How to establish priorities in equipment maintenance?

We know that establishing priorities in maintenance can often be a challenge. This happens because this profession become a way to put out the fire in organizations, instead of keeping the equipment working correctly to avoid contradiction during the staff work.

Because of that, it is common to find organizations that do corrective maintenance instead of preventive maintenance, making the work process even more difficult. A good way to balance even more the performance is to precisely define priorities using criticality analysis.

Let’s think together: once the organization has established which are the equipment that show big failures risks, it is possible to make action plans that structure a maintenance involving its three types: corrective, preventive and predictive.

Well, but how can that be done? Although the manager job is defined which way makes the most sense to company or equipment, there are two techniques used and bringing good results: MTBF (Mean Time Between Failures) and MTTR (Mean Time to Failure).

- MTBF: calculates the mean time between failures that guides the frequency required to carry out maintenance activities;

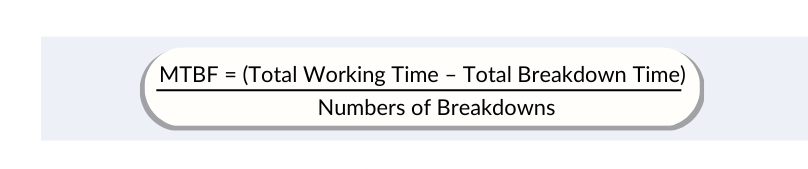

To calculate this equipment availability time, we will use the formula:

MTBF: Total Working Time – Total Breakdown Time / Numbers of Breakdowns

Total Working Time: The ideal time that the equipment should work if no failure happens.

Total Breakdown Time: Time the equipment had to be stopped to make some repairs.

Numbers of Breakdowns: The number of times the equipment had to stop for repairs.

- MTTR: indicates the mean time required to repair a failure.

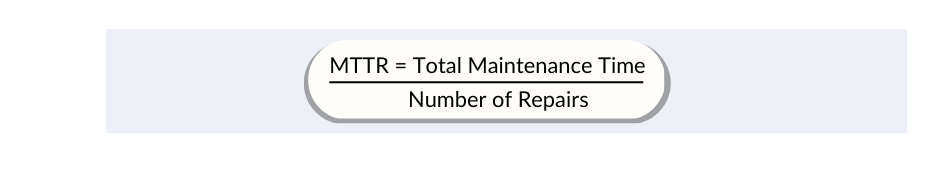

To calculate this equipment downtime, we will use the formula:

Total Maintenance Time: Time the equipment had to be stopped to make some repairs.

Number of Repairs: The number of times the equipment had to stop for repairs.

Do you notice how equipment criticality analysis can make all the difference in your day-to-day? By prioritizing which equipment needs maintenance, you can optimize your company’s resources, balance predictive, preventive, and corrective adjustments and ensure the safety of all employees.

So, what did you think about our article? Take the opportunity to continue your reading and find out how to continue the equipment maintenance process!