Contents

How does equipment performance influence the replacement decision?

Keeping equipment running well in an industrial environment is hard work that relies on several types of analyses. To determine whether a piece of equipment delivers reliability and availability, you need data on the behavior of these assets. This data can be measured in several ways. Here are some examples:

- Condition monitoring: analyzing temperature, vibration, pressure, and other parameters is crucial to understanding asset performance. With this monitoring, you can identify imminent failures or wear on the equipment. Some sensors can even be used to capture real-time data and enable predictive analysis.

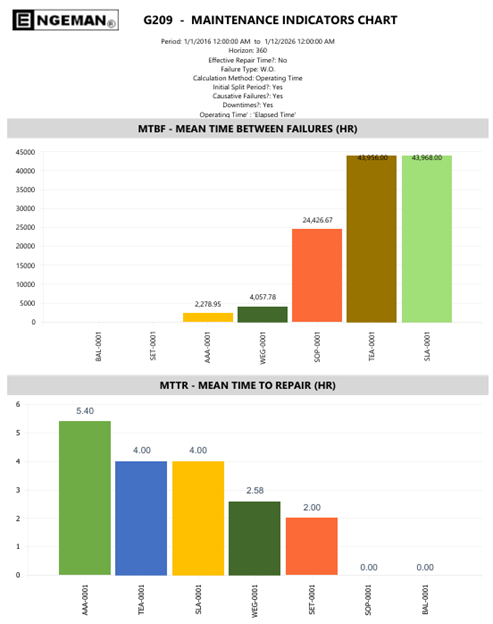

- Maintenance indicators: measuring data such as MTBF (Mean Time Between Failures) and MTTR (Mean Time to Repair) is essential to better understand your equipment. This way, you will know the average response time they have shown and how much this has been costing you in maintenance.

- FMEA: Failure Modes and Effects Analysis is a technique used to identify potential failures in equipment, systems, or processes. It analyzes three key aspects: Cause, Effect, and Failure Mode. It helps you better understand the equipment, identifying the root cause of problems for decision-making and preventing future failures.

But after all, how does this information and these analyses help in deciding whether to replace a piece of equipment?

Many times, we think the easiest decision is simply to discard what is causing us a problem instead of fixing it. Before moving toward a replacement decision, we need to carefully analyze whether the equipment in question is causing more loss than profit and why it is causing this loss, since in many cases the cause is correctable, and this is where maintenance provides the solution.

That is why analyzing the data mentioned above is so important. However, beyond analyzing equipment behavior to support decision-making, it is also important to know how to measure its useful life cycle.

How to measure equipment useful life?

The useful life of a piece of equipment is the period during which it can operate effectively before needing to be replaced. The natural wear of an asset is inevitable until it reaches the end of its useful life.

It is important to perform this analysis so that you can work correctly with the necessary maintenance at each phase of the equipment’s useful life. But how can this be measured properly?

In general, some manufacturers already provide this information when the equipment is purchased. Overall, the calculation of an asset’s useful life is done by analyzing the years of operation versus the hours of use per year.

However, to measure it accurately, you must pay attention to several factors that can influence the extension or even cause a premature end of useful life, such as:

- Climate exposure

- Operation without adequate pauses

- Lack of maintenance or inadequate maintenance

- Incorrect operation by the work team

Taking these and other factors into account, you can use several techniques to measure equipment useful life more accurately.

One of the most commonly used techniques is the bathtub curve.

Why analyze the bathtub curve?

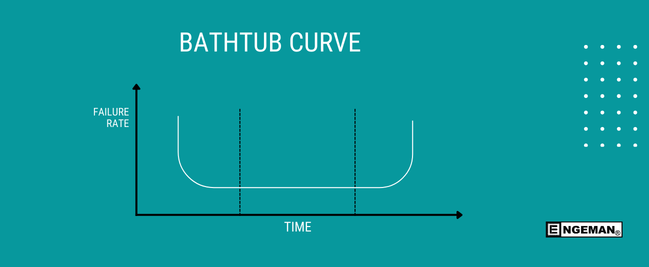

The bathtub curve is a concept used in reliability engineering and equipment maintenance to illustrate the asset failure rate over its useful life. It has this name because its shape resembles the profile of a bathtub, with three distinct phases.

- Initial Phase: in this first phase, there is a failure rate often caused by manufacturing defects or installation issues. This period is called “infant mortality” and occurs right after the equipment begins operating.

- Normal Phase: after the initial phase, if maintenance is performed correctly, the failure rate typically decreases and stabilizes. During this phase, failures usually stem from the natural behavior of the equipment. The failure rate here is generally low and constant.

- Final Phase: as the equipment ages, failures due to obsolescence begin to increase. Failures become more frequent as the equipment approaches the end of its useful life.

When each phase of the asset is recognized, it becomes easier to adopt techniques and tools to increase the equipment life cycle. Each phase will require a different decision-making approach.

In the initial phase, the maintenance demand is not as high; the key is to observe the equipment’s behavior, follow the manufacturer’s guidelines, and not overlook any signs of failure.

In the second phase, set up an appropriate maintenance schedule, do not let it lapse, but do not overdo it either. Use a maintenance management software such as Engeman® to create the proper schedules.

In the last phase, pay closer attention and apply techniques to analyze equipment behavior so that maintenance becomes as accurate as possible.

After all behavior-based analyses and maintenance activities have been peformed, you will be able to identify the moment when the asset has reached the end of its useful life. It is at this point that replacement will be more worthwhile than preventive maintenance. Until then, do not make any hasty decisions and invest in maintenance management software to help you measure all equipment data and manage maintenance activities.

How does Engeman® help measure equipment behavior?

As we have seen above, analyzing equipment behavior is one of the most important factors in helping to decide whether or not you should replace a piece of equipment. Only in this way will you make a truly assertive replacement.

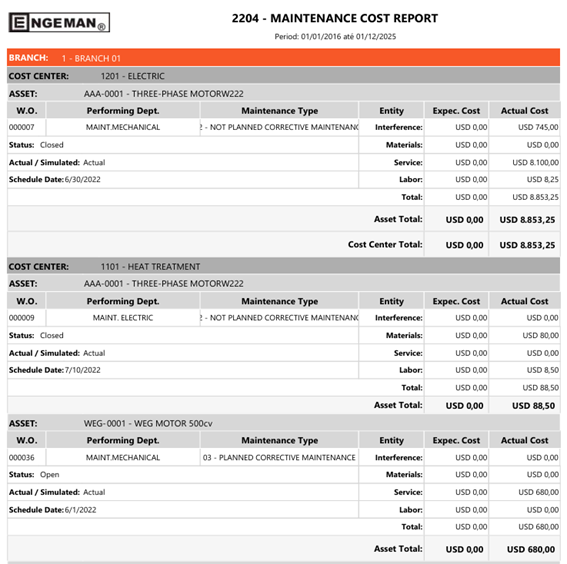

We must make this decision based on concrete and reliable data. Using a maintenance management software that provides charts and reports on asset behavior is indispensable.

Engeman® offers more than 300 charts and reports not only on equipment, but also on materials, labor control, and maintenance costs, among others. But since the focus here is asset behavior, let’s look at some relevant charts and reports:

Engeman ® Maintenance Cost Report

Engeman ® Maintenance Indicators Chart

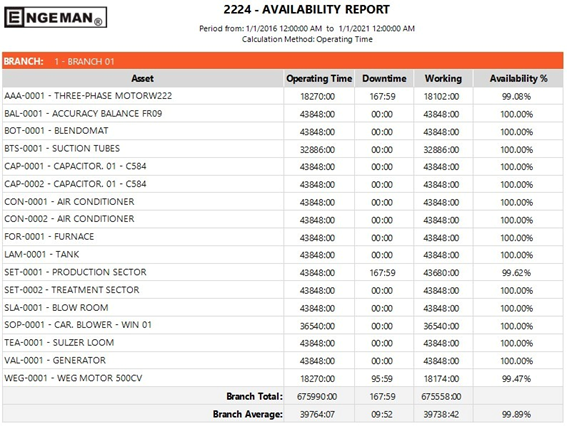

Engeman ® Availability Report

With these and other reports that Engeman® offers, you will be able to develop an effective maintenance plan based on asset behavior and also determine the right time to replace equipment in your company.

Conclusion

In this article, we have seen that choosing proper maintenance instead of replacing equipment can be more advantageous in the long term. Regular maintenance helps extend equipment’s useful life, reduce unexpected failures, and avoid high replacement costs.

Thus, in many cases, investing in effective maintenance management and a robust CMMS is the best choice, as it offers a good balance between cost and performance, ensuring fewer outages and greater reliability in equipment operation.

To learn more about this topic, schedule a demo with our team. We look forward to hearing from you!