Contents

What is Materials Inventory?

Materials Inventory is the verification of stock by counting and listing all stored products. The main function of inventory is to identify what is in stock, in order to define what needs to be purchased and also to list whether there were any losses of goods.

As best practices, the inventory management team and the maintenance management team must work together, in order to align common points. For example:

- Define the minimum and maximum stock quantity of each material: this definition is linked to several factors such as material cost, its importance to maintenance, its turnover, storage conditions, occupied space, and even its suppliers.

- Define consumption and turnover of inventory: this step is directly related to the first one, since consumption and turnover vary for each material. Materials with higher turnover and consumption will likely be replenished more frequently.

- Warehouse management: involves studying the physical organization of the maintenance warehouse to speed up material withdrawal when necessary, considering safety both for personnel moving through the environment to avoid occupational accidents, and for the part itself, which often has considerable value.

Responsibilities of the inventory manager for inventory control

We have frequently mentioned here the responsibilities and duties of the maintenance team and its importance for maintenance management. We always emphasize how important it is to keep all performed activities recorded, as well as how a structured plan makes it possible to extract essential reports for decision-making.

With the team responsible for inventory control, it is no different. There are responsibilities that belong exclusively to the inventory control and management team. And if they perform them with excellence, the entire company will certainly benefit. There are management techniques that facilitate this control.

But before applying any methodology, the inventory manager needs to pay attention and answer questions such as:

1. What is the criticality of the items in stock?

This question may be the most important of all, as it involves understanding the criticality of each item in stock. Answering this question helps the inventory manager in decision-making.

Example: there may be parts with very high cost and no national production or delivery. When a purchase need is identified, delivery may take weeks. If it is an essential part for the operation of machinery that runs continuously without interruptions, the production team will face serious problems.

Therefore, when the inventory manager understands the importance of a part in stock, they will pay attention to all details and organize its replenishment accordingly.

2. Which items must be kept in stock?

Once the criticality of each part is known, this question must be aligned with the needs of the maintenance team. It is necessary to consider items required for planned maintenance, but above all, the inventory must contain materials, parts, and consumables essential for unplanned corrective maintenance, as this directly impacts production.

3. What is the right time to replenish inventory?

This must also be aligned with maintenance management, which, based on its planning, can inform us when certain materials not currently in stock will be needed. In this way, the company can schedule purchases at the right time.

This directly impacts financial management, which can better plan cash flow.

4. What should be kept as safety stock?

Safety stock means defining the minimum quantity of consumables or products required in case of emergency. In maintenance, emergencies can be varied.

Therefore, inventory and maintenance managers must study together and understand what safety margin should be maintained for each item.

Small parts, such as screws, may have larger quantities than parts such as bearings or housings, which occupy more space. However, stock quantities must always be aligned with emergency needs and turnover.

Methodologies that support inventory control

Once particularities are aligned, it becomes possible to achieve more accurate inventory management. To further facilitate this process, certain methodologies can be applied. See below some that are relevant:

- OPEX Method: the company can track the breakdown of basic costs, that is, understand the allocation of each cost to arrive at the total budget. For example, the “OPEX” method, which stands for Operational Expenditure.

When discussing maintenance inventory, this refers to understanding the costs of acquiring and storing materials. The more services that involve part replacement, the higher the inventory acquisition cost will be.

With this information, the company can organize itself financially to keep inventory updated without harming business health.

For inventory management itself, there are also methods such as:

- LIFO Method (Last In, First Out): the last material that enters stock is the first to leave. Its application depends on company needs and the type of material involved.

- FIFO Method (First In, First Out): the first material to enter stock is the first to leave. This method is widely used for products or consumables with expiration dates or warranties.

- ABC Curve: aims to analyze and classify inventory items based on priority. The ABC curve helps make more informed and strategic decisions, allowing resources to be focused where they generate the greatest impact and value.

- Just in Time Method: translated literally as “right on time,” meaning the company purchases the exact quantity of material needed for a specific maintenance activity. This method is commonly used for high-value materials, which are registered in inventory only for direct consumption.

What are the main benefits of inventory management for maintenance?

In addition to cost reduction already mentioned, other benefits include:

- Better maintenance planning: the maintenance manager can be more accurate when calculating time and expected costs for executing activities described in each plan, knowing that specific materials are in stock or have a confirmed delivery date.

- Greater availability of machines and equipment: this impacts production and even asset lifespan. The greater the availability of machines, the less interference in production.

Failing to perform preventive maintenance due to lack of material in stock can cause serious damage to machinery or even irreversible failures. All this simply because inventory management was not properly performed clearly not a smart decision.

Thus, inventory management is highly relevant in the maintenance universe, and to perform it, materials inventory is essential.

How to manage inventory in Engeman®?

Engeman®, which is a CMMS tool, manages inventory for materials used in maintenance. See how inventory management can be performed in Engeman®:

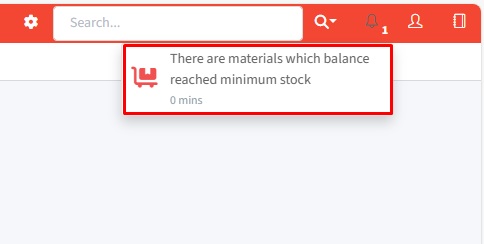

- The system sends minimum stock alerts;

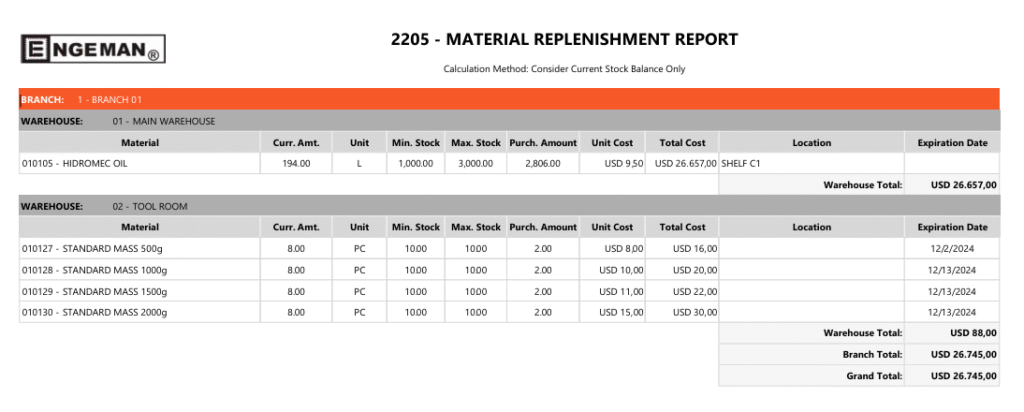

- Generates replenishment reports;

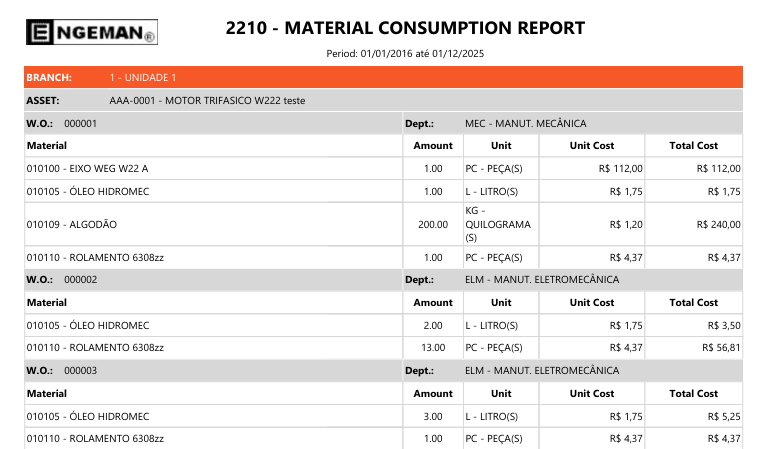

- Informs material consumption used in work orders;

- Controls material expiration dates;

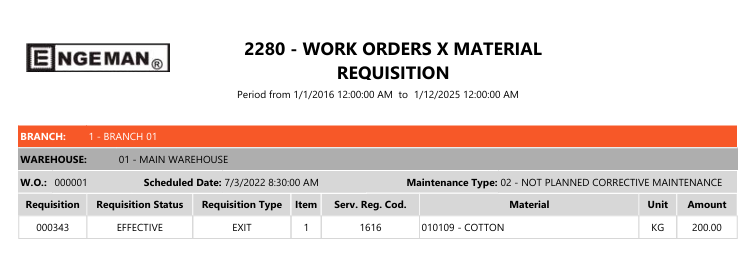

- Tracks requests by work order;

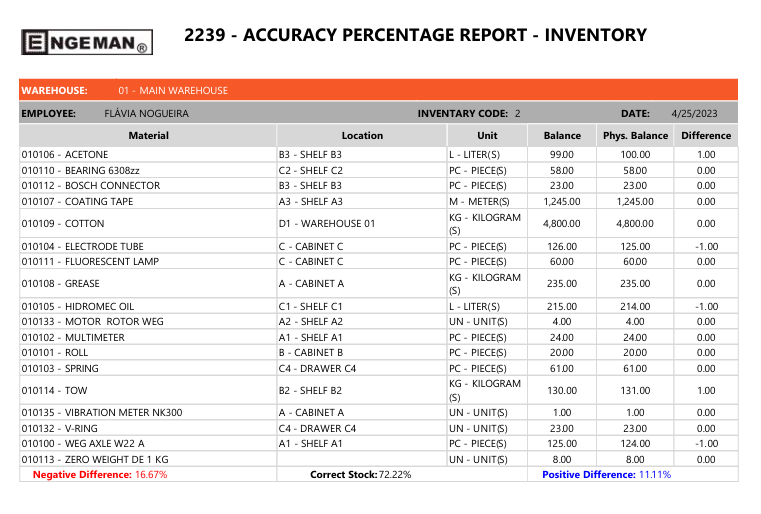

- Controls inventory and even presents the accuracy percentage of each inventory performed.

Engeman® also allows tracking warranty records for materials informed in work orders.

Conclusion

There is no single best method, there is one thatf best fits your company. In many cases, it may be necessary to apply more than one method due to the diversity of materials required for maintenance management.

In addition to these methodologies, it is essential for companies to use materials management software, especially when inventory management is performed simultaneously with maintenance management.

For this purpose, relying on a CMMS tool that also manages inventory greatly facilitates the work of both departments.

If your company needs to improve maintenance inventory control, our software can be the ally you are looking for. Schedule a meeting to learn more about Engeman® and start implementing this improvement as soon as possible.