Contents

- What is the definition of reliability?

- What is Reliability-Centered Maintenance (RCM)?

- What is the function of reliability?

- Why is availability important for an efficient maintenance plan?

- What is the difference between maintainability and availability?

- What are the advantages of management planning based on these precepts?

- How Engeman® supports RAM analysis and RCM management

What is the definition of reliability?

In maintenance management, according to the Brazilian standard NBR 5462, reliability refers to the probability or percentage of proper operation within a certain period of time of machines, systems, and/or items within the production chain.

This measure is performed by analyzing data referring to the equipment’s performance history and estimating its future operation.

Thus, it is possible to determine, for example, the percentage chance that a hydraulic turbine will operate according to its specifications over the next 8,000 hours.

This measure represents a key component of RAM analysis, used to determine system reliability and availability.

What is Reliability-Centered Maintenance (RCM)?

The goal of every industry is to achieve maximum efficiency in its services, equipment, and processes, isn’t it? However, this can only happen when there is a safe, healthy, and reliable work environment.

The RCM methodology, Reliability-Centered Maintenance, focuses on a systematic approach to planning maintenance activities. It considers the reliability, availability, and safety of an asset.

Reliability becomes essential knowledge in these cases, as it is determined by the probability that a piece of equipment or production cell will function normally.

This methodology defines the best policies for managing failures and can be applied in any type of environment, without excluding other forms of maintenance.

What is the function of reliability?

Although each business has different characteristics and data, it is based on the following principles:

- Extend the performance time between scheduled shutdowns;

- Ensure cooperation between all people involved in maintenance operations;

- Improve maintenance productivity;

- Create a proactive and planned approach;

- Adopt efficient tactics for solving failures and problems.

To perform Reliability-Centered Maintenance (RCM), the maintenance supervisor must consider some key questions such as:

- What are the functions of the asset in its operational context?

- In what ways can these functions fail?

- What are the causes of these failures?

- What happens when they occur?

- What is the importance of each of these consequences?

- What should be done to predict and prevent these occurrences?

- What should be done when no viable proactive maintenance techniques are found?

The answers to these questions make a maintenance supervisor more confident in decision-making. Remember that these processes are iterative and rely on a clear understanding of the objectives.

Why is availability important for an efficient maintenance plan?

Availability and reliability are closely related indicators in RAM planning.

Availability determines the amount of time that a piece of equipment is available for work requests or in operational condition.

Poor planning generates disorganized maintenance and reduces equipment availability. Thus, availability is an indicator that must always be monitored and improved.

What is the difference between maintainability and availability?

In other words, maintainability is an extremely important concept for the success of any maintenance management plan.

For example, if a component fails frequently and there are no proper conditions for repair or replacement, this can lead to loss of productivity, increased accidents, and higher expenses.

In such cases, it is necessary to create mechanisms and promote changes in the work environment to overcome these obstacles.

What are the advantages of management planning based on these precepts?

With the application of these principles in the business environment, maintenance managers can more easily identify when equipment evaluations and corrections should be carried out.

As a result, the definition of failure probabilities, the standardization of restoration procedures, and the creation of operational codes of conduct are some of the advantageous consequences for companies.

Increased equipment lifespan

By dedicating care to each machine in the production flow, the wear and tear naturally caused by time is significantly reduced.

This allows companies to keep their machinery running longer without losing product quality and delaying the need for costly new equipment investments.

Cost-effective optimization

Due to the reduced need for new machinery, companies minimize long-term expenses. Thus, investments can be redirected to other sectors or production assets nearing full depreciation.

These precepts also facilitate the planning of more effective corrective actions, positively influencing the reduction of unnecessary maintenance costs.

Improved operational performance

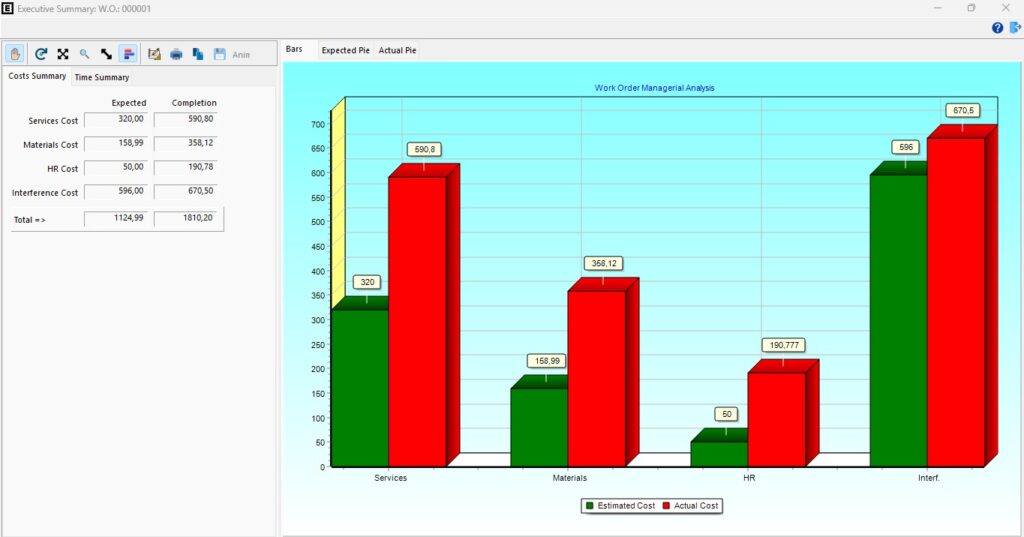

The technical knowledge of supervisors, supported by efficient maintenance management software, directly impacts the real availability and reliability of company machinery.

The better the operational performance managed by technical teams, the lower the maintenance costs and the risks of future failures caused by equipment unavailability.

Management database retention

Companies that apply these precepts become more aware of performance variations in their machinery history. This enables supervisors to identify the best maintenance tactics and store this information in specific databases.

Such data are extremely useful in RAM analysis, as they provide a universal basis for measuring performance across all production stages, maintenance, operation, and inspection.

Agility of technical teams

With these databases, teams have the necessary support to perform their tasks efficiently.

Therefore, companies’ expenses with specialized technical labor decrease considerably. Employees, now more agile and better prepared, complete tasks faster and with fewer errors or rework caused by lack of information.

How Engeman® supports RAM analysis and RCM management

The consumer market has never been as demanding and competitive as it is today. Because of this, industrial activities must be carefully planned and analyzed. The concepts of reliability, availability, and maintainability only work correctly when maintenance supervisors have up-to-date information.

Trying to perform all these activities manually leads to poor performance indicators and negatively affects overall management results. At such times, using maintenance management and control software is the best option.

With it, it is possible to monitor everything that happens, generate reports, control material consumption, create event histories, balance human and financial resources, and perform many other functions that bring flexibility to professionals.

Let’s take Engeman® as an example to demonstrate how it can assist in RCM (Reliability-Centered Maintenance) management:

Function

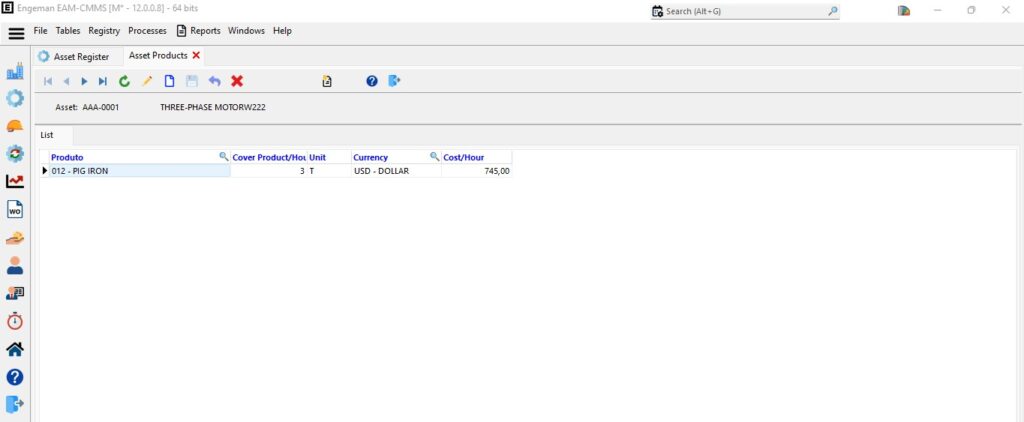

In RCM, equipment is responsible for fulfilling specific purposes within the production chain, as well as its subcomponents, this is called a function.

Each piece of equipment can perform one or more functions, which are referred to as “products” in Engeman®.

When defining the functions of each piece of equipment, we must define:

- The purpose or function, represented in the image by the Product field. In this case, the loom’s function is to produce four different types of fabric.

- The expected output, or productive capacity per hour, is represented by the Prod. Cap/Hour field.

- The financial loss caused by a functional failure, represented by the Cost/Hour field.

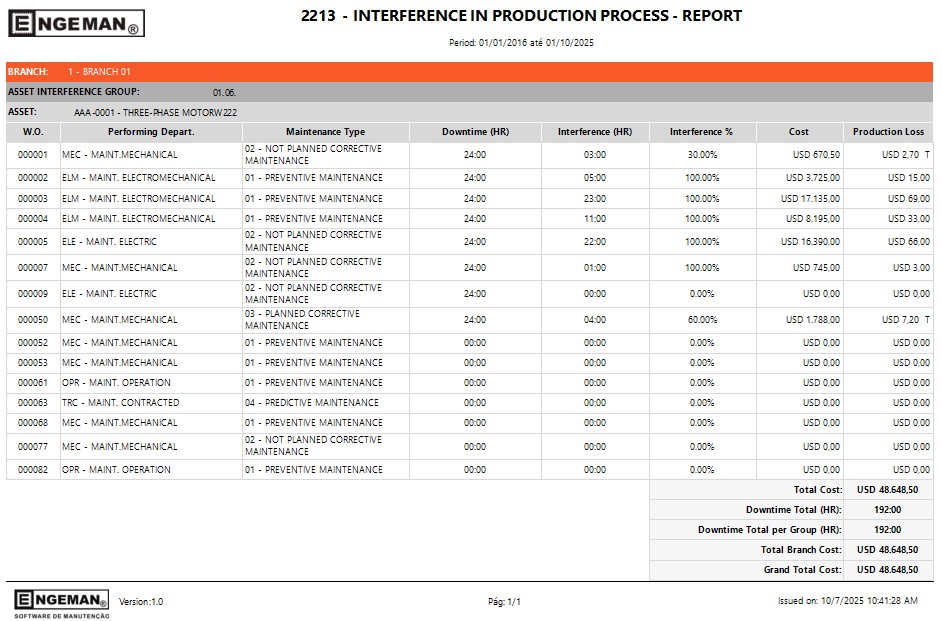

With this, the primary and secondary functions of the equipment and its subcomponents are defined, allowing control, especially over losses caused by maintenance interventions on these assets, as shown in the image below.

Functional Failure

A failure is defined as the loss of a function. A functional failure occurs when any asset becomes incapable of performing a function at a performance level acceptable to the user.

If the loom shown above stops working, this represents a total functional failure. If it continues to operate but at a reduced capacity, it is a partial functional failure.

Usually, production control software and telemetry systems can record these situations.

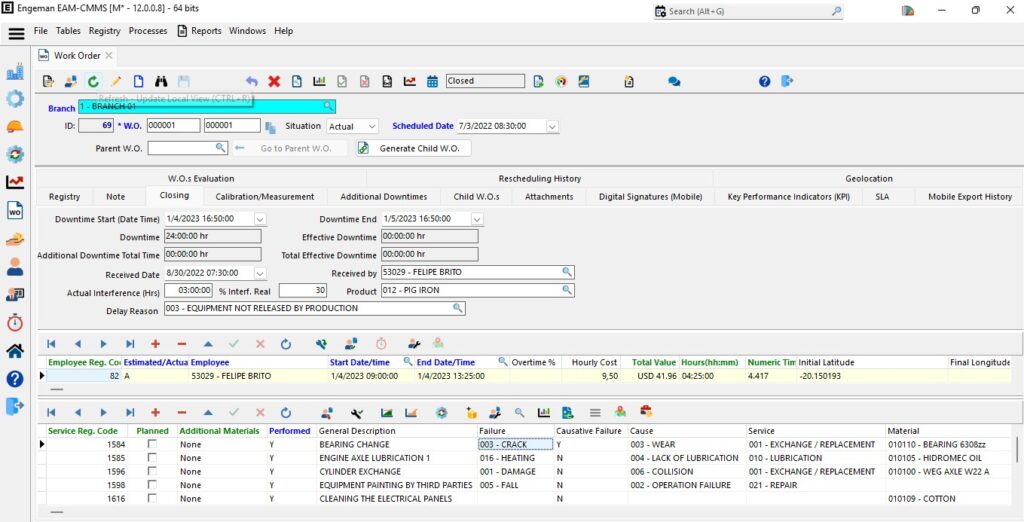

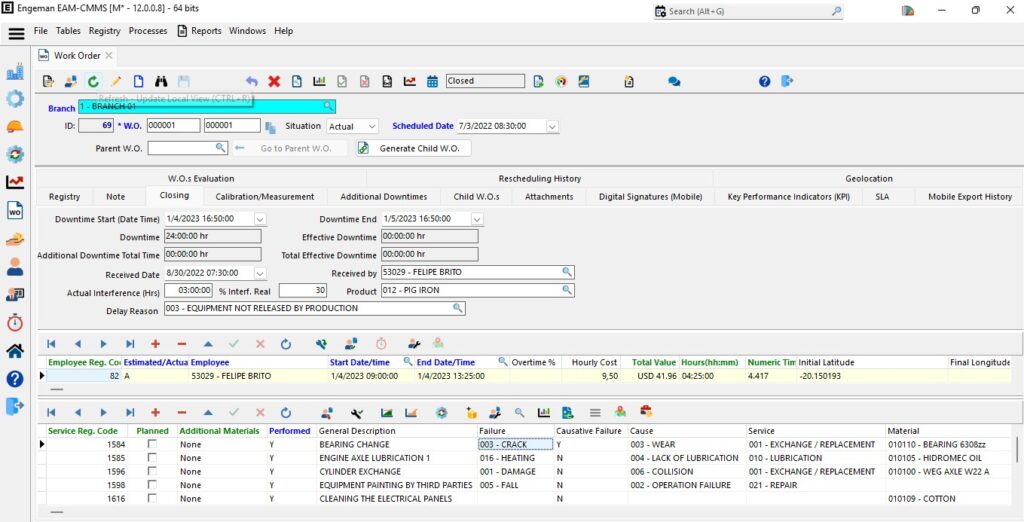

In maintenance, if an activity results in a complete or partial equipment shutdown, this functional failure is recorded in the work order, specifying:

- When the functional failure began (Equipment Stopped field);

- When the equipment is returned to operation (Equipment Working field);

- The percentage of functional failure — total (>100%) or partial (<100%) (% Actual Interference field);

- The function was affected by the failure (Product field).

With this information, it is possible to identify which failures occurred during the period and the financial impact they caused.

Failure Modes and Corrective Actions

Based on their functions, assets can fail in several different ways. In RCM, every event that can cause a functional failure is identified.

This identification includes events recorded in the failure history, as well as potential failure modes that have not yet occurred but are likely to happen in the future.

In Engeman®, this is organized in several steps:

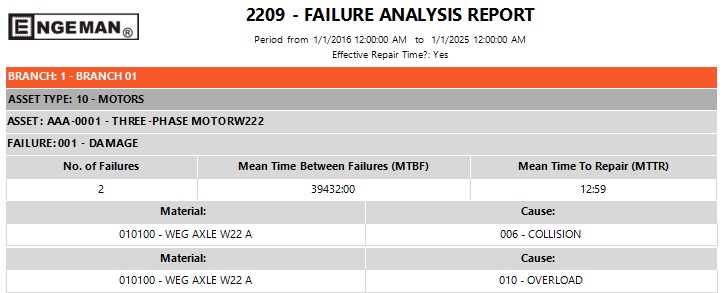

- Identifies occurrences, events, and causes that can compose the functional failures and failure modes. These are listed in Engeman® tables with the same names.

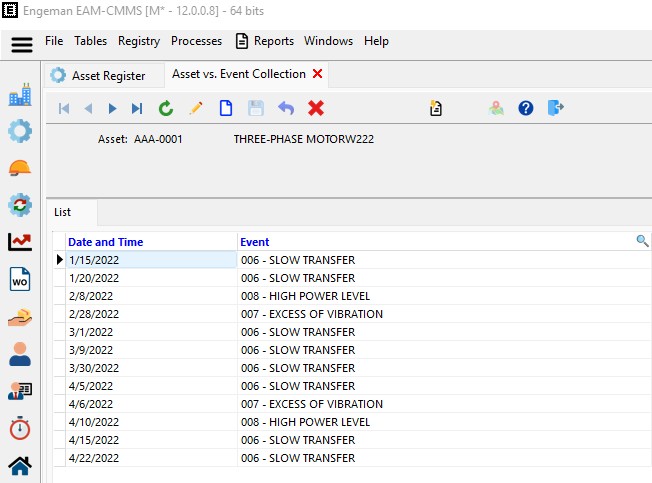

- With daily use, Engeman® starts collecting this data automatically, either from generated work orders or through telemetry, which detects symptomatic events in the equipment.

- Finally, all items are related to maintenance planning, linking each failure mode to a corresponding corrective action.

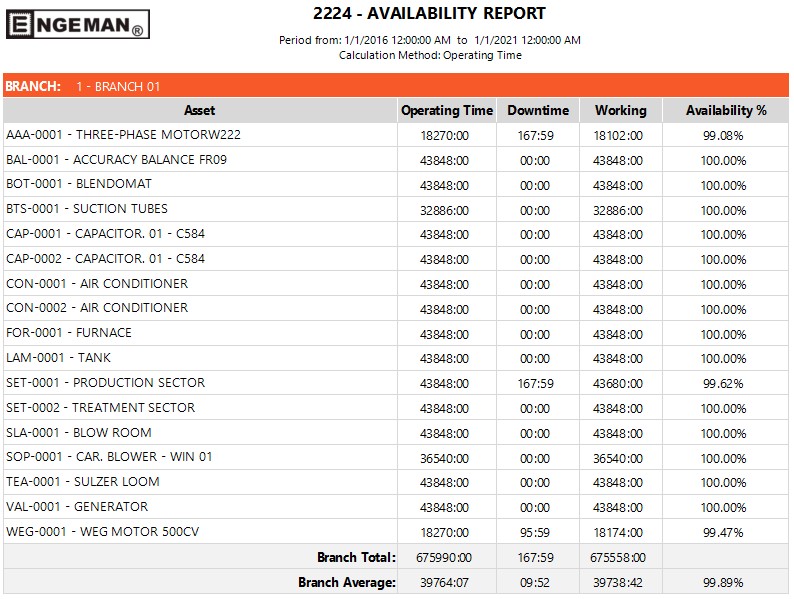

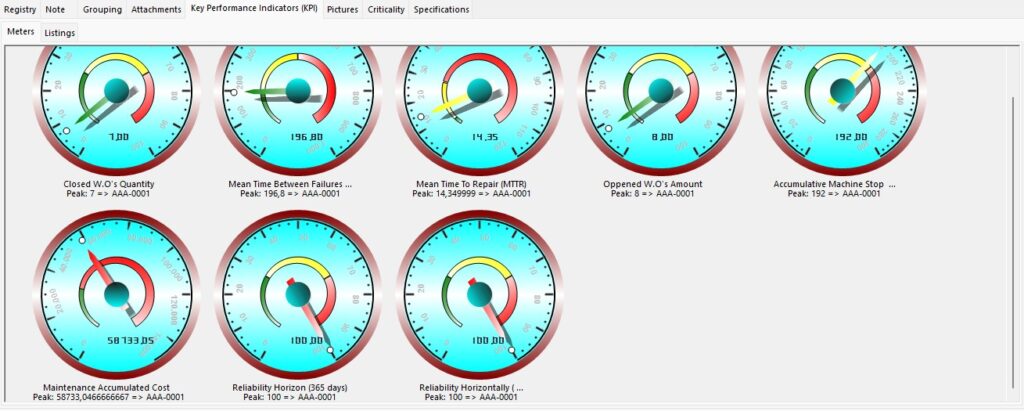

With these few steps, Engeman® enables companies to evaluate production losses, identify which equipment has higher or lower availability during a given period, and assess the reliability of each asset in the process, as shown in the following reports.

Find out more about how Engeman® can help your company boost its results by talking to one of our specialists! Stay up to date with the maintenance world by following us on our social media channels: Facebook and Instagram.