Contents

What is a Dashboard?

A dashboard, or control panel, is a visual interface that presents important data and information in an organized and easy-to-read way. It is used to monitor and analyze the performance of a system, project, or company by displaying metrics, charts, tables, and other visual indicators.

The use of dashboards is a form of visual management, as it provides visual boards and digital panels that can be displayed on computers and televisions for a better understanding of the situation of a specific department.

Visual management, therefore, is a methodology that involves clear and visible exposure of important information about the performance and condition of processes or assets. This practice aims to facilitate communication, decision-making, and continuous improvement by making critical information accessible to all team members and stakeholders.

Dashboards are very useful and versatile tools and can be used in a wide variety of areas, such as business, sales, finance, marketing, maintenance, and others.

What are the 3 types of Dashboards?

There are several types of dashboards, depending on the goals and the type of information to be displayed. Below, we will discuss the three most common types of dashboards:

- Operational Dashboard:

The operational dashboard aims to monitor and manage daily operations. It provides a detailed, real-time view of the performance of essential processes and activities, helping to quickly identify problems and make informed decisions to improve operational efficiency. Examples include quality control dashboards or general monitoring dashboards.

- Tactical Dashboard

A tactical dashboard is a data visualization tool designed to support planning and execution at the intermediate level within an organization. It serves as a link between strategic dashboards, which focus on long-term objectives, and operational dashboards, which monitor daily operations. Tactical dashboards help managers make decisions that optimize processes and improve efficiency in the short to medium term.

- Strategic Dashboard

The strategic dashboard presents high-level information and metrics that are essential for defining and monitoring long-term business strategies. It provides high-level metrics, strategic KPIs, and robust historical data. Examples include performance dashboards and growth plan dashboards.

Which tools can be used to implement Visual Management?

Some tools are commonly used to implement visual management, such as:

- Visual Boards

Using traditional whiteboards or magnetic boards, where information is manually and regularly updated, is still an effective way to implement visual management, although it can be costly. These boards should be placed in strategic locations where all team members can easily see them.

- Visual Signage

The use of colors, charts, and symbols to highlight important information facilitates quick data interpretation. For example, using different colors to indicate asset status (green for operational, yellow for maintenance, red for stopped).

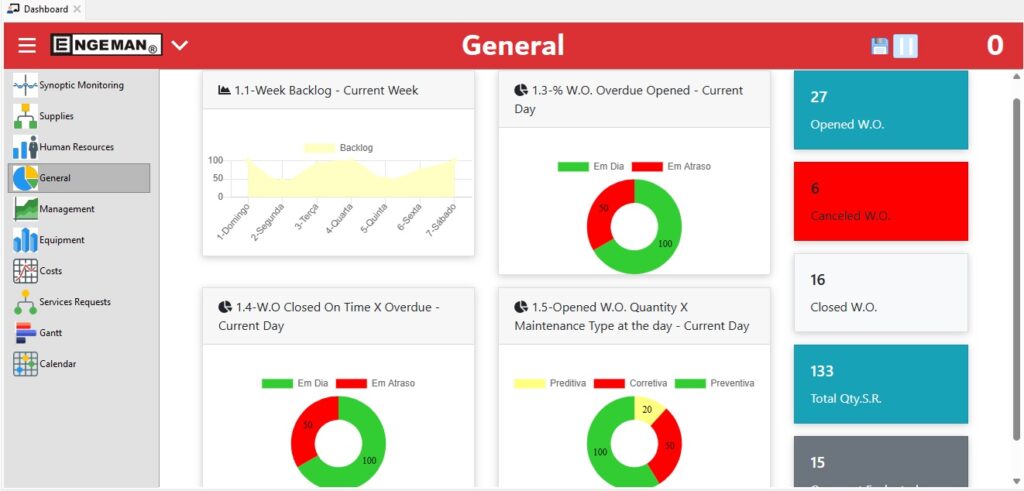

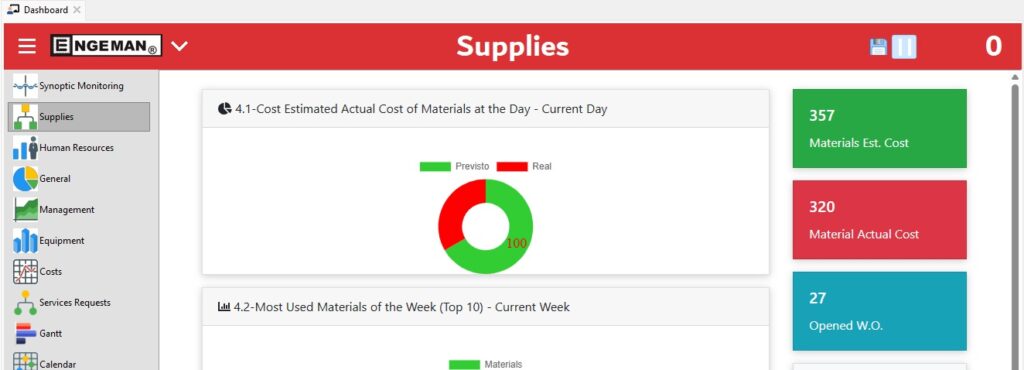

- Maintenance Management Software

Specialized software, such as Engeman®, offers interactive and customized dashboards to monitor and present maintenance data. These systems can integrate with other technologies, such as IoT sensors, to provide real-time data, further improving the accuracy and efficiency of maintenance management.

How to implement Visual Management?

To implement visual management effectively, follow these steps:

- Identify Critical Information: Determine which data is essential for monitoring and decision-making. This may include asset status, KPIs, maintenance calendars, work orders, alerts, maintenance history, resource availability, and resource planning. Remember: there are common points, but also specific cases for each manager.

- Choose the Right Tools: Select the tools that best meet your team’s needs, such as visual boards, maintenance management software Engeman is already prepared for this or visual signage. The tools should be easy to use and update, ensuring that information is always accurate and up to date.

- Develop an Update System: Even when using software, establish a process for regular information updates, ensuring that data remains current and accurate. This may include assigning responsibility for updating visual boards or using automated systems for data collection and display. In most cases, important data comes from the execution of work orders and closing them regularly in the software is extremely important.

- Train the Team: Train the team to use the tools and interpret the information presented. Training should include the importance of visual management, how to use selected tools, and how to interpret data to make informed decisions. There is no possible decision-making if the information presented is not understood.

- Monitor and Adjust: Monitor the use of visual management and adjust necessary to improve the effectiveness and efficiency of indicators. This may include periodically reviewing displayed data, updating the tools used, or providing additional team training.

What should a Maintenance Dashboard include?

By now, you have seen the importance of visual management, but for it to be effective, dashboards must contain key information that ensures a comprehensive view for maintenance managers.

Below, we list some elements that every dashboard should include. As examples, we reference the screens of Engeman® software, which provides intuitive and complete dashboards for maintenance management.

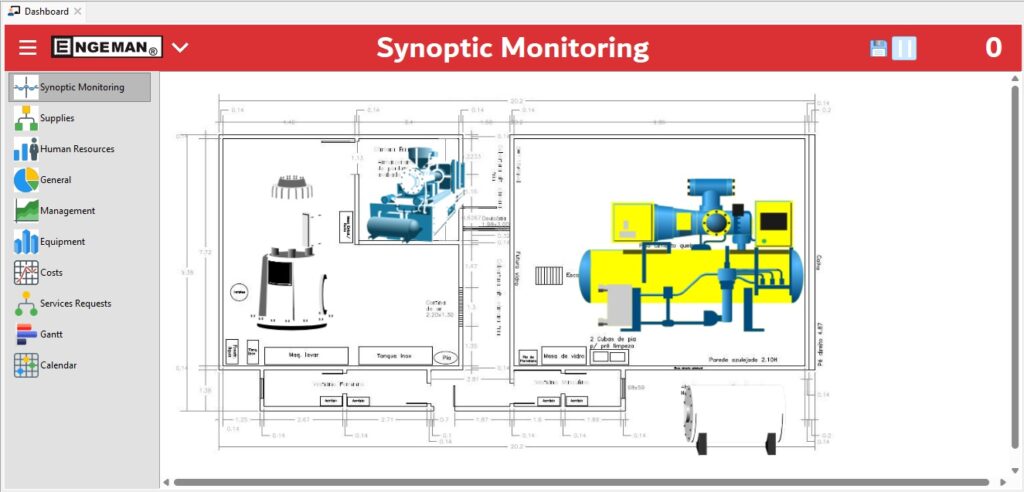

1. Asset Status

Indicating the current condition of assets is fundamental. Information on whether assets are operational, under maintenance, or stopped helps the team prioritize activities. In addition, visualizing asset status allows quick responses to changes, ensuring operations continue without unnecessary interruptions. In Engeman®, this is referred to as Synoptic Monitoring.

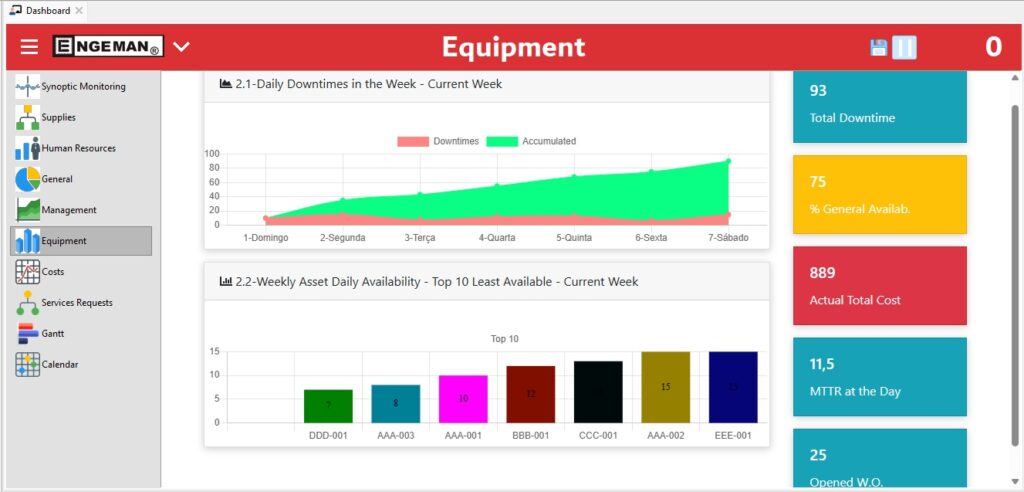

2. Performance Indicators (KPIs)

KPIs are crucial metrics for evaluating asset performance and maintenance activities. Some of the most common KPIs include:

- MTBF (Mean Time Between Failures): Measures the average time between asset failures, helping assess reliability.

- MTTR (Mean Time to Repair): Measures the average time required to repair an asset after failure, indicating maintenance of team efficiency.

- Availability: The percentage of time assets are operational, reflecting overall maintenance effectiveness.

- Maintenance costs: Monitoring costs helps control budgets and identify areas for savings.

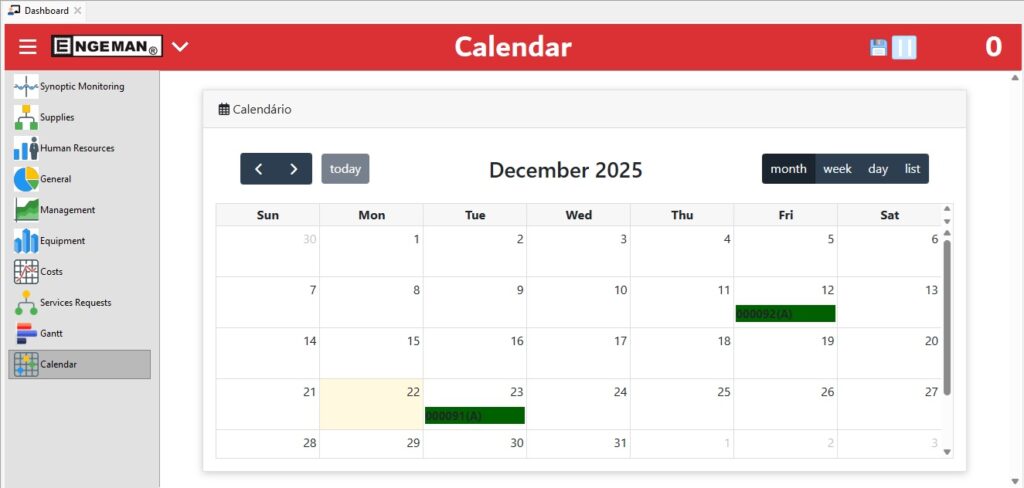

3. Maintenance Calendar

Having a visible maintenance schedule, including preventive, predictive, and corrective maintenance, allows better organization and planning. The calendar helps ensure all maintenance activities are carried out at the appropriate time, preventing unexpected failures and extending asset lifespan.

4. Work Orders

The status of work orders such as pending, in progress, and completed tasks is essential for tracking maintenance activity progress. This helps teams prioritize tasks and ensure all required maintenance is completed efficiently.

5. Alerts and Notifications

Alerts regarding imminent failures, delayed maintenance, or urgent intervention needs are essential for fast and effective responses. These alerts help teams focus on areas requiring immediate attention, preventing more serious issues in the future.

6. Maintenance History

Detailed records of performed maintenance, including actions taken, replaced parts, and associated costs, are essential for analyzing asset performance over time. Maintenance history helps identify failure patterns and improvement opportunities, supporting predictive maintenance and process optimization.

7. Resources and Materials

Visibility into spare parts of availability, tools, and other resources required for maintenance is critical to avoid delays. Visual management ensures all resources are available when needed, facilitating maintenance execution.

8. Resource Planning and Allocation

Effectively planning and allocating human and material resources is crucial for maintenance efficiency. Visual management helps identify gaps or excesses in resource allocation, allowing teams to adjust plans and ensure maintenance is carried out efficiently.

Importance of Dashboards in Asset Maintenance

Dashboards are widely used to support fast, informed decision-making. They can be customized to display the most relevant data for each user or organization, providing a clear and objective overview of operations and activities.

Below are additional reasons why dashboards are so important for maintenance management:

1. Transparency

Transparency is one of the pillars of visual management. Making asset and maintenance information visible to everyone promotes a culture of trust and openness.

For example, displaying equipment status operational, under maintenance, or stopped allows all team members to quickly understand the current situation. This eliminates isolated information and helps avoid misunderstandings, promoting a work environment where everyone is aware of what is happening.

2. Communication

Improving internal communication is one of the main benefits of visual management. When critical information is displayed clearly and accessibly, the need for frequent status update meetings is reduced.

Teams can communicate more efficiently, relying on up-to-date data visible to all. This is especially important in maintenance environments, where coordination between different teams can be complex. Dashboards facilitate this coordination by ensuring everyone is aligned.

3. Fast Decision-Making

In maintenance environments, the ability to make fast, informed decisions can be the difference between continuous operation and prolonged downtime. Visual management allows decisions to be based on real-time data, which is essential for quick and effective interventions.

For example, if a critical asset shows signs of imminent failure, visible and updated information allows the maintenance team to act quickly, minimizing production impact.

4. Monitoring and Control

Visual management facilitates continuous monitoring of assets and maintenance activities. This is crucial for identifying issues before they become critical and for discovering opportunities to improve maintenance processes.

Additionally, it provides a clear view of performance and maintenance progress. With visible KPIs such as MTBF and MTTR, teams can monitor asset performance directly on the dashboard and adjust strategies as needed.

Download MTBF and MTTR spreadsheet!

5. Team Engagement

Making information accessible to all team members promotes accountability and engagement. When teams have access to performance data and can see the impact of their work, they feel more involved and motivated to contribute improvements.

Visual management also encourages shared responsibility, as everyone can see how their actions affect overall performance. This creates a collaborative and proactive work environment where teams are constantly seeking improvement.

Conclusion

Visual management, combined with asset maintenance dashboards, is a powerful practice that provides transparency, improved communication, fast decision-making, continuous monitoring, and team engagement.

When implemented effectively, organizations can significantly improve asset management, reduce downtime, and extend equipment lifespan, resulting in more efficient and profitable operations.

Investing in visual management is not just an operational improvement, but a cultural shift that promotes accountability, collaboration, and continuous improvement within the organization.

For this purpose, always rely on Engeman® software to implement the best management practices. Schedule a demo and learn more!