Contents

- What is the availability of maintenance?

- What’s the difference between availability and reliability?

- What are the types of availability?

- How to calculate maintenance availability?

- What is the importance of availability for companies?

- How to ensure equipment availability?

- How does Engeman® treat asset availability?

What is the availability of maintenance?

Maintenance availability is the ability of a system or equipment to remain in full operation when needed. It can be affected by several factors, such as equipment reliability, how quickly failures are detected and repaired, and the effectiveness of preventive and predictive maintenance practices.

Equipment availability directly impacts an organization’s productivity and profitability. We can easily imagine the chaos in a production process if assets are unavailable, leading to unplanned downtime and severe financial consequences.

The Brazilian standard NBR-5462 addresses, among other topics, asset availability and defines when equipment is considered available or unavailable.

What’s the difference between availability and reliability?

Availability and reliability are commonly related to efficient management, as the correct functioning and the time that can be counted on with certain equipment are directly linked to the company’s success.

When talking about availability, it refers to the ability of a system to be in operation for the desired or planned time. It considers both the equipment’s operating time and the time it is out of operation due to failures.

Reliability, on the other hand, refers to the ability of a system to perform its functions consistently over time, that is, the equipment performs its functions as expected and without failure.

As said, both concepts are fundamental for the effective maintenance and reliable operation of equipment and systems in any industrial department.

What are the types of availability?

In the industrial context, availability can be classified into a few types, considering whether the machine has been in usable condition or not. The most relevant types in industrial maintenance are:

- Physical Availability: the availability that considers the time at which the system or equipment can function without failure. In this case, downtime for repairs, inspections, and equipment shutdowns is not considered. It would be the basic availability of a system or component based on its design and the absence of unexpected events that could interfere with its operation.

- Inherent or Intrinsic Availability: the availability that considers the downtime for corrective maintenance. This availability calculation is important to measure the efficiency of the maintenance team, for example. In this case, we can conclude that the availability of the equipment in this group is that it was not broken. For its calculation, the MTBF and MTTR are considered.

- Operational Availability: the availability that considers both planned downtime and unplanned downtime, such as failures, corrective maintenance, preventive maintenance, etc. It is the calculation that represents the probability of a piece of equipment being in operation or in a condition to work during the period production expects. We will see in the next topic how operational availability is calculated since it is widely used in the maintenance department.

In different industrial and operational contexts, other specific types of availability can be defined, depending on the needs and performance evaluation criteria of a system or equipment.

How to calculate maintenance availability?

For this calculation, we will use operational availability. Operational availability is important because it helps the manager understand the time that the machine has been stopped for repairs, and thus it is possible to strategically design scheduled stops and not be surprised.

This indicator will determine if the equipment is available for work orders or work requests or if it is in operational condition, that is, it tells us about the downtimes on the production line.

Observations:

- In Uptime, the total operating time is considered, which would be the total calendar time minus the total maintenance time, assuming that the machines operate continuously, without idle time.

- In Downtime, the total repair time in the period is considered.

By the World Class definition, the result of the availability calculation must be greater than or equal to 90%.

What is the importance of availability for companies?

Like so many other indicators in maintenance, availability is fundamental to a bold maintenance manager’s strategy. Since the manager needs to avoid unplanned downtime, understanding when machines are available prevents production from suffering losses and delays. Some reasons to understand equipment availability are:

- Cost reduction: Equipment that is frequently unavailable or breaks down frequently can result in higher repair costs, production delays, and lost revenue. By calculating availability, it is possible to identify areas of improvement to reduce operating costs.

- Production planning: Knowing equipment availability allows for more effective production planning. This helps avoid unplanned interruptions that could affect production and the delivery schedule, ensure contract fulfillment and directly impact customer satisfaction.

- Improved reliability: Knowing equipment availability allows managers to identify weaknesses in systems and take steps to improve equipment reliability and durability. This can include preventative maintenance and investment in operator training.

- Assertive decision-making: Equipment availability provides concrete data that can support investment decisions in new equipment, preventive maintenance, hiring personnel, and other operational improvement initiatives.

How to ensure equipment availability?

To achieve high asset availability rates, it is essential to perform preventive and predictive maintenance, in addition to having well-defined and executed plans, along with good control of materials.

Have you ever imagined your equipment suffering unexpected downtime on weekends or non-working days, and you don’t have the necessary parts for maintenance? This can result in a much greater loss than the value of the part itself, highlighting the importance of availability for continued use.

Therefore, to ensure equipment availability, it is necessary to be aware of maintenance and plans according to specific needs, such as:

- Preventive maintenance: Conducting regular inspections and replacing components according to an established schedule, reducing the risk of failures.

- Predictive maintenance: Using data and continuous monitoring to anticipate failures and perform interventions before serious problems occur.

- Periodic plan: Determination of a specific period for performing maintenance.

- Specific date plan: Like the periodic plan, but with fixed dates, for example, the 1st of each month or December 20th of each year.

- Accumulative plan: Control through the measurement of accumulated quantity, for example, maintenance will occur on the asset every 200 hours worked.

These are just a few possible plans that can be used to increase the efficiency of your equipment and consequently its availability.

How does Engeman® treat asset availability?

It is possible to quickly create maintenance plans and monitor the limits established in these plans through collections made with the Engeman® software.

Through Engeman® Mobile, maintainers can work quickly and effectively, collecting data even offline, reducing the use of paper, and saving time since it will not be necessary to write down the information on paper and then transfer it to the system or a spreadsheet.

Data collection can also be performed through Engeman integration with intermediary systems that automate these collections.

With the collections, it is possible to monitor the limits of each plan, and Engeman® allows the definition of alerts when the established percentage is reached, thus enabling maintenance to be scheduled at the most opportune time.

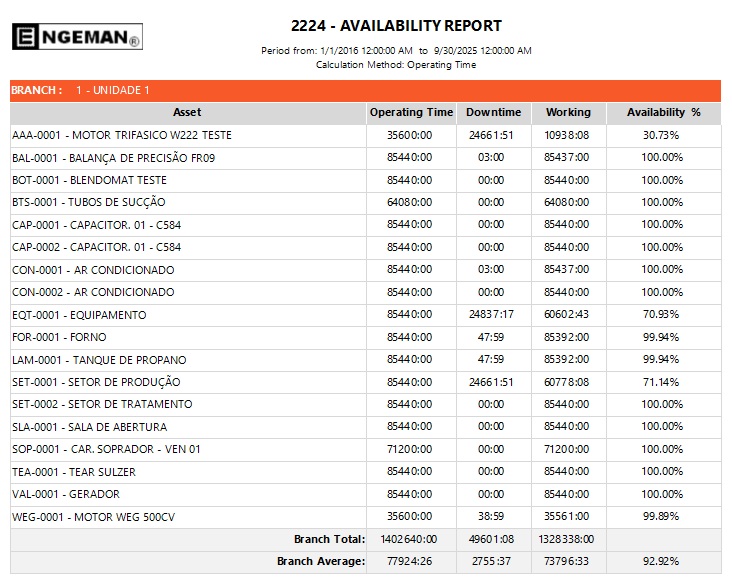

There are also several indicators, such as graphs and reports, with the availability calculation already prepared. These indicators are calculated through the data entered in the system daily, such as the opening of a work order, the time spent maintaining that asset, and the impact of that equipment during maintenance.

Engeman® can be organized for plan implementation, providing control and effective organization for maintenance performance. It is even possible to search for plan indicators, allowing practical visualization of reports and graphs with the availability of each asset.

For more information on how Engeman® can help you properly control your indicators, contact our experts! Understand all the possibilities that Engeman® can bring to your maintenance!