Contents

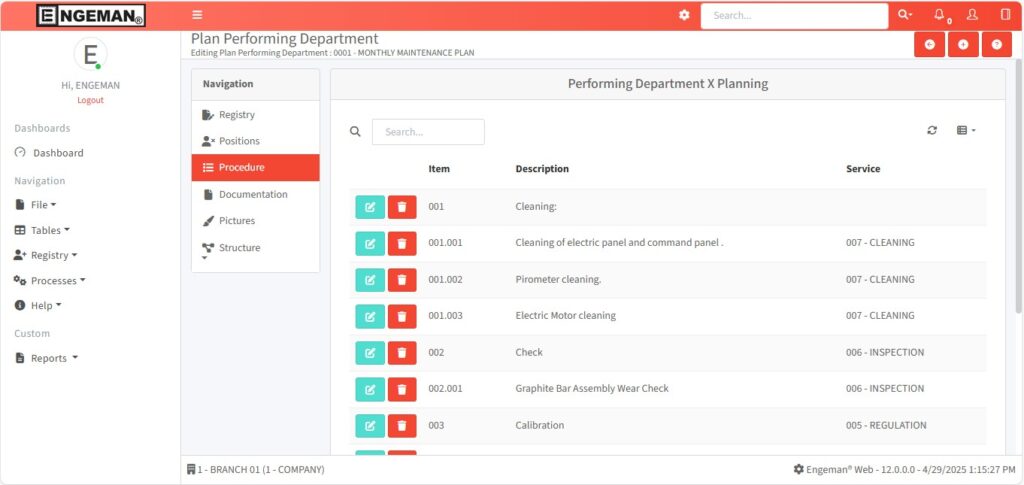

1. Poorly defined Work Order activities

If the scheduled activities of the Work Order or Maintenance Plan are not clearly defined, either in terms of completeness or at least include the most critical tasks, they will constantly require updates during performance. This not only affects expected timelines but can also increase costs, leading to delays, rescheduling, and cancellations.

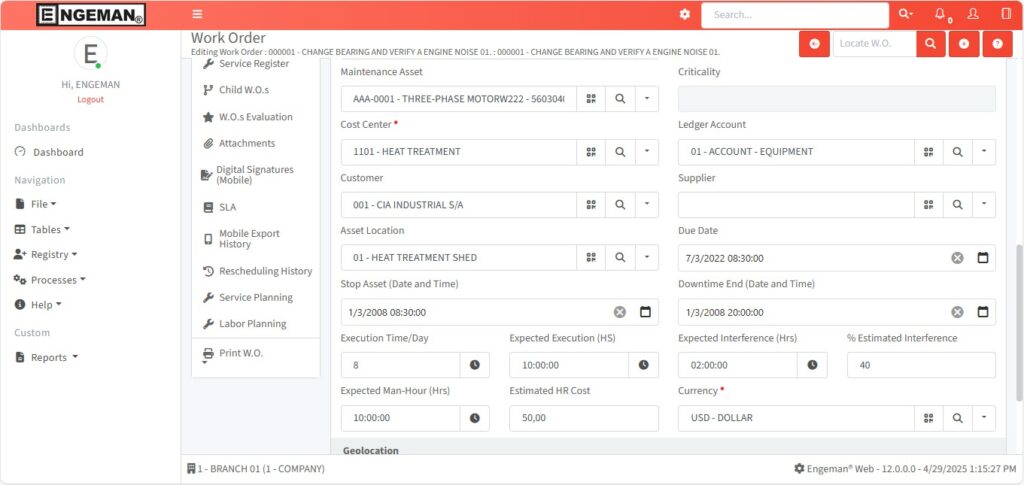

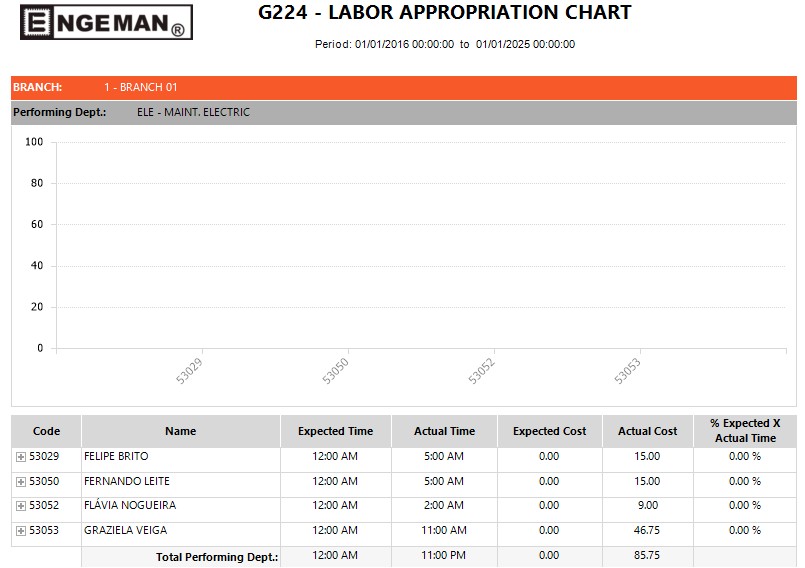

2. Inaccurate time estimates in Work Orders

Every activity, whether part of the maintenance plan or directly in the work order, can have an estimated execution time, including labor, procedures, equipment downtime, or other interferences. When these times are poorly defined, they can cause execution issues. In Engeman®, it is possible to define all deadlines associated with each service.

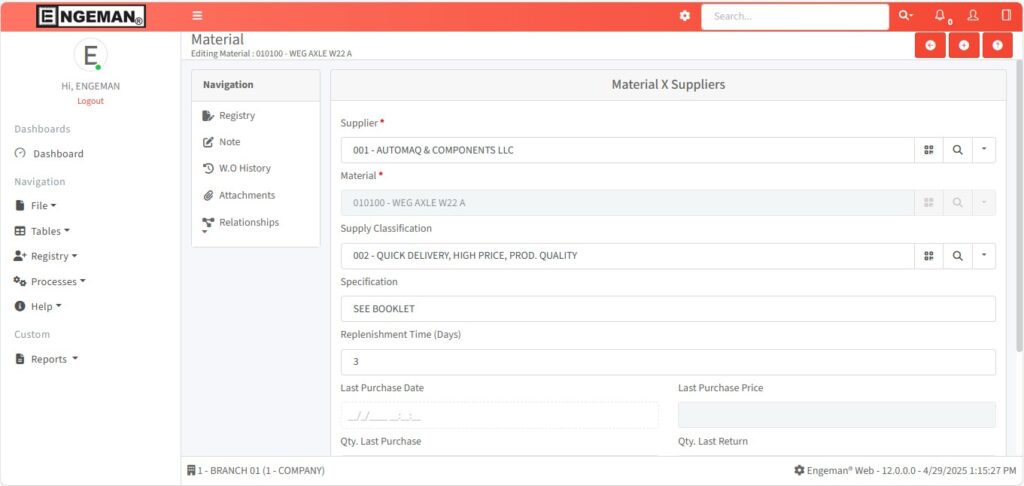

3. Delays caused by materials or services suppliers

Maintaining a history of all supplier information helps speed up maintenance processes since all data is centralized. When suppliers fail to deliver parts or services on time or at the agreed cost, switching suppliers may be necessary, which can impact both maintenance time and costs, leading to delays, rescheduling, and cancellations.

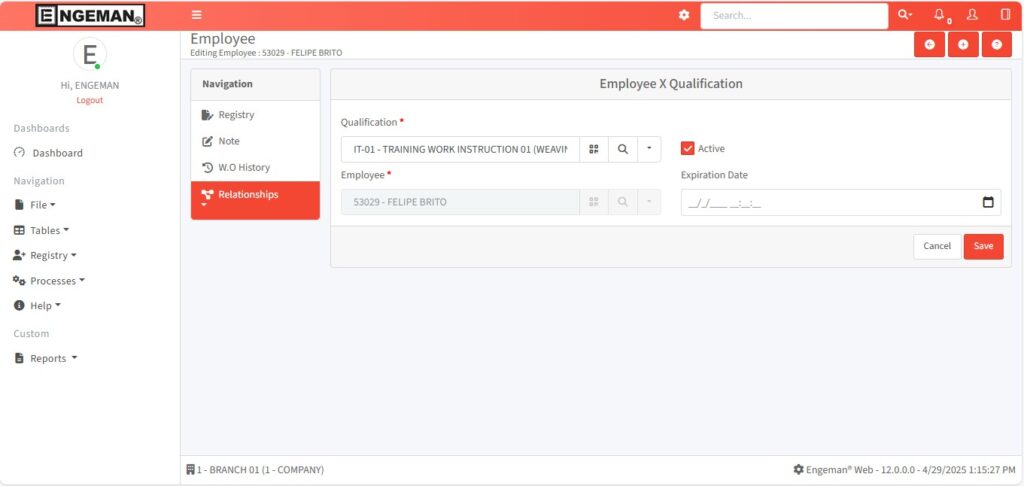

4. Unqualified or overloaded employees

Keeping accurate records of employee qualifications is critical. Knowing which employee can perform each work order activity, or whether training has expired, ensures service quality and prevents delays. Overloaded or unqualified personnel directly impact process efficiency. Centralizing this information in one system can prevent performance issues.

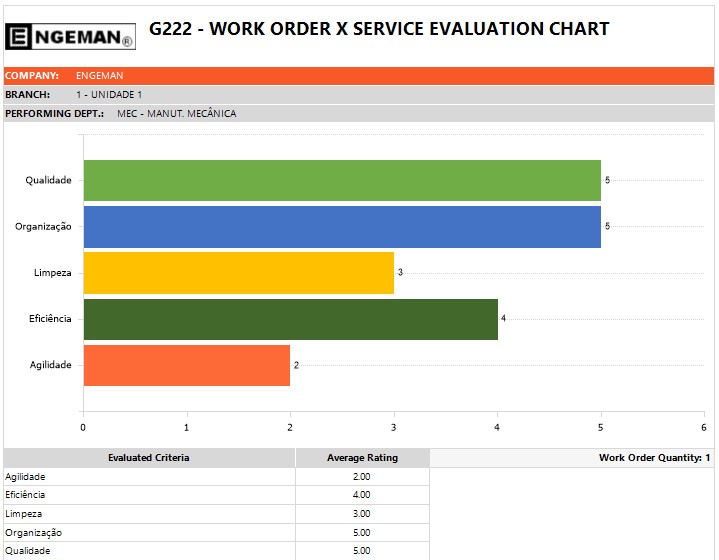

5. Lack of maintenance quality control

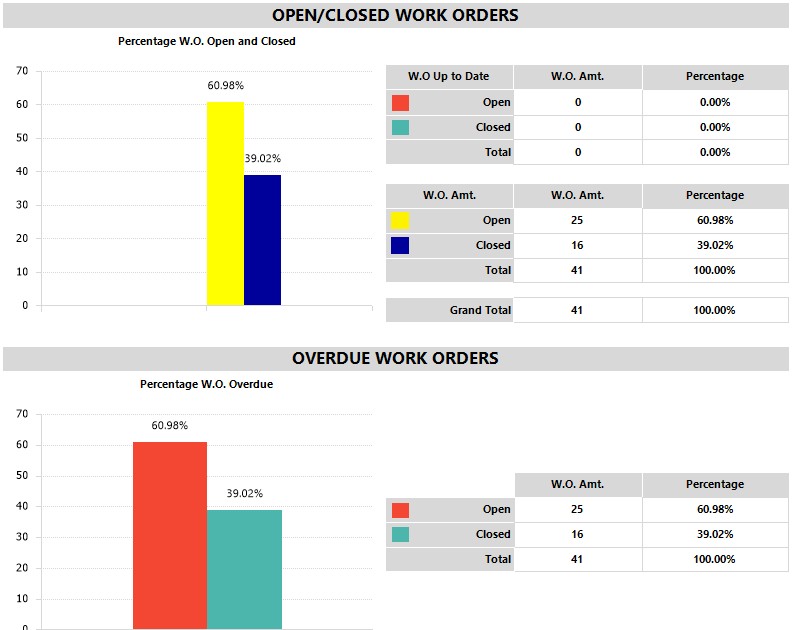

The lack of service quality control is closely linked to rejected services and increased costs. Maintenance software provides reports that help maintain service quality and ensure proper progress of all work orders without unexpected downtimes.

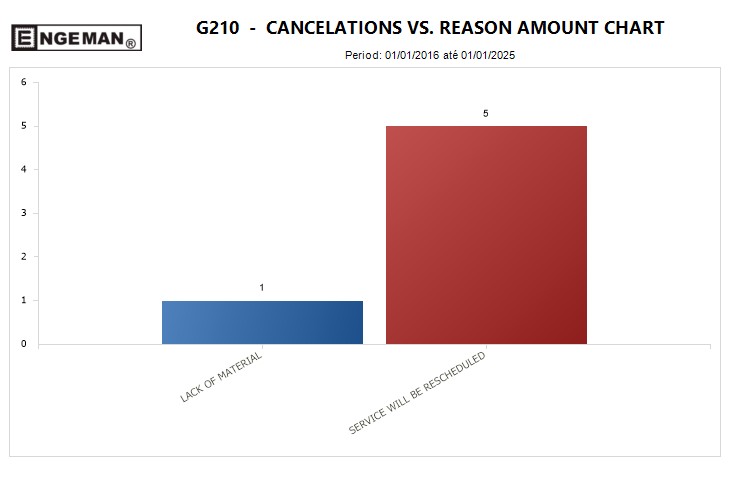

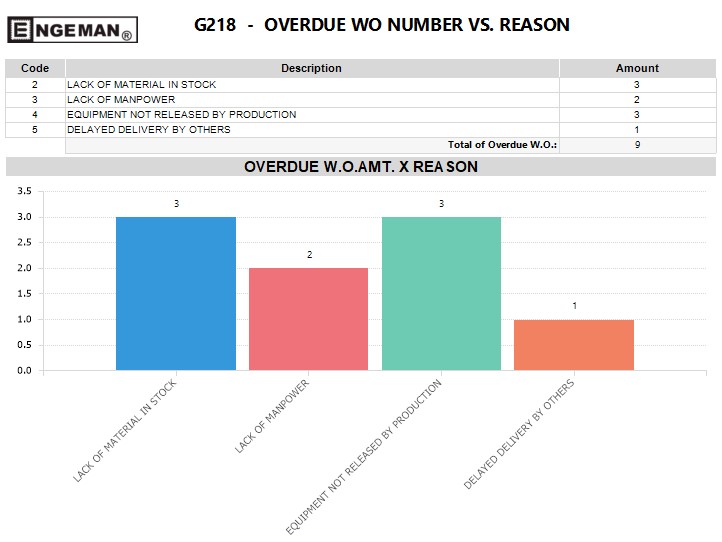

Analyzing reasons for cancellations, delays, and rescheduling provides valuable data for maintenance management, including schedule impacts, product quality, and process safety.

Increasing occurrences of these issues indicate a need for more workforce training or additional maintenance staff. Balancing available personnel ensures better maintenance outcomes.

The same analysis can also guide budgeting, parts consumption, production needs, and other critical maintenance insights.

Creating a matrix of main causes and defining mitigation strategies allows for faster decision-making and schedule adjustments.

During execution, maintenance managers can assess the probability of cancellations or rescheduling, compare the current situation against the matrix of common causes, and propose solutions to mitigate and recover schedules.

To avoid unexpected downtimes and work order delays, having maintenance software supports success, agility, reliability, and productivity. Schedule a personalized online demo to see how work order delays can be prevented with Engeman®.