Contents

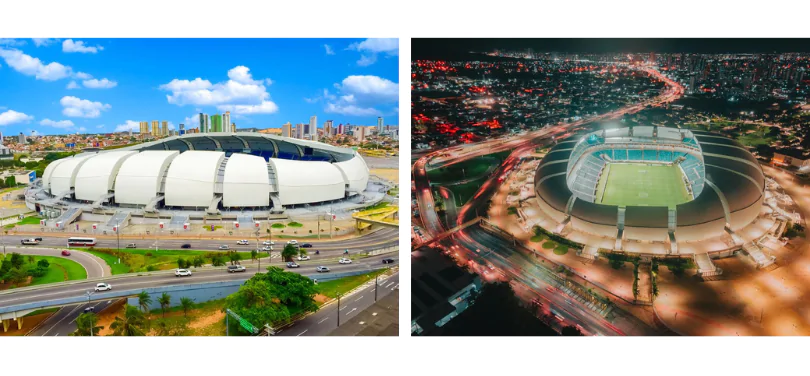

Learn more about Arena das Dunas

Arena das Dunas, located in Natal-RN, was built to host the 2014 World Cup and staged four matches. In addition to hosting football games, the space also accommodates various activities, including large events, entertainment, exhibitions, a comprehensive coworking facility, and more.

Arena has a structure that offers comfort and security, with hospitality lounges, 39 boxes with exclusive bathrooms, locker rooms, a media and TV center, areas for restaurants, a gym, commercial spaces, and indoor and outdoor parking. All this in a structure in which care for sustainability has been present since the beginning of the works.

It was the first stadium in Brazil to receive the ISO 55001 international certification for asset management and maintenance. Proof that it has excellence in asset management and equipment preservation. This is the Arena das Dunas, the stage of great emotions!

Problems faced before Engeman®

When a company does not use software to control maintenance, the data needs to be recorded many times in spreadsheets. Although spreadsheets have many features, they are still limited. It is not possible to assertively control many assets and search for histories in a simple way.

Luiz told us that, before implementing Engeman®, the Arena das Dunas “did not have the history of maintenance, and everything was controlled through the drive”. This prevented a more assertive control of data from past interventions.

Another point he told us is that “all W.O.s were opened through Google Drive, so we had the need to implement a tool to facilitate this process.”

Results achieved with Engeman®

After facing problems with the lack of histories and difficulties with W.O.s, Arena das Dunas implemented Engeman®, and the results were excellent. Luiz told us the following:

“It has become much easier to open a work order. We can quickly see who will perform the service, and the software automatically assigns it to the appropriate department. It made the day-to-day maintenance much easier. Today, we have a history of everything that happens in the Arena.”

And it doesn’t stop there. Using specialist software like Engeman®, you can plan for the next year and decide your budget estimates even before this year ends. Isn’t it fantastic?! Do you want to know what Luiz told us? Check it out…

“We have all the preventives registered, and control is easy. If I want to get a report for the next year of everything that will be performed and on what date, I already have it here in the software. Everything that was done behind me too, I have a record of all the maintenance that was performed, materials requisitions that were used to perform that maintenance. With all this, I can build several indicators from this history.”

Integration with other systems

After reading the results above, you must be thinking: “a really good software is one that adapts to the specific needs of the company and that still manages to integrate with other tools on the market to further optimize maintenance processes”. Well, I agree with you! And I tell you that Engeman® has all this too. Not to stay only in my words, look at what Luis told us:

“Arena das Dunas has been undergoing an implementation of Power BI. Therefore, several departments are being served by this tool, and the maintenance part was one of them. So, we contacted Engeman, requesting the API that communicates with Power BI. Throughout the year, we have been implementing this with the help of the Engeman team, and today we have communication as Power BI. With this, we were able to graphically release all indicators to the company. All in an easy and visual way. It was an excellent advance that we had this year here. Today, we can already see the entire Engeman® database through Power BI.”

The flexibility that software has in adapting and integrating with other tools is a differential of Engeman®, designed to meet all the demands of any maintenance department.

Using Mobile Module

So far, you have seen how Engeman® can help with your maintenance and help your managers make assertive decisions. But what about mobility? As it is a stadium and even has third-party partners in maintenance, a mobile solution is ideal for the maintenance controls of the Arena das Dunas.

“Today, it is essential to have this mobile alternative because the entire maintenance team has the application. Some outsourced companies also use this tool, such as the contractor responsible for air conditioning. Engeman® Mobile is used to send W.O., requisitions, etc. Today Engeman® is integrated with our system, and all material requisition from the warehouse is done through the software. When the employee closes a W.O., he is required to insert the evidence, that is, the photos of the service that was performed. So, mobile today is extremely important for the operation of Arena’s maintenance. It optimized our management process”, reported Luiz.

Advantages of using Engeman®

We also asked Luiz for 3 advantages that he could indicate to us about the use of Engeman®. He pointed out:

- Possibility of software integration;

- Mobile module, which optimizes and streamlines all the control of preventive measures with the generation of automatic W.O.;

- Control of indicators based on maintenance histories.

“Each asset has periodicity, so this is already registered in Engeman® from the asset register. In this way, the W.O. generation is automatic, and this enables dynamism for us. We have the annual preventive maintenance plan inserted in the software“, said Luiz.

Arena das Dunas and Engeman® Partnership

In this article, we show you how the use of specialized software can change your results, with more agile and reliable management. Arena das Dunas tried some tools, and Engeman® proved to be the most suitable for their specific needs.

“In 2016, we felt the need here at Arena das Dunas to have maintenance management monitoring software. To date, the experience has been very good, we have been able to fully monitor both preventive and corrective maintenance, and this has been very valid for us in monitoring the asset as a whole. Whenever we need help, we contact the Engeman team, and the team always offers us support to find a way to be able to perform the changes,” Luiz Henrique Gomes Popoff, responsible for operations and facilities – Arena das Dunas.

So, did you see how even stadiums can achieve more agility and reliability in maintenance management with the help of specialized software? How about bringing all these benefits to your company? Talk to our experts and see in practice how Engeman® can help you.

And if you are still not convinced, explore other success cases from our champion maintenance management customers.