Contents

Learn more about TERMOV

TERMOV – Outsourcing of Material Movement Ltda – is located in Belo Horizonte – MG and works with the rental of forklifts and handling equipment. In addition to leasing, it also sells new and used equipment, offers application engineering and equipment customization, provides technical assistance, and sells and manages traction batteries.

Termov offers practical and economical solutions, always focusing on innovation and transparency. With almost 30 years of experience in the market, Termov works to offer the best in structure, technology, product excellence, and service quality.

Problems faced

“The big problem before implementing the software was the fact that we basically worked with spreadsheets. The difficulty was really in filling out these spreadsheets, posting data, storing them, checking stock, maintenance interventions, etc. Everything was based on numbers and not on histories,” said Silas.

At Termov, despite having trained professionals and well-structured spreadsheets, data control and management became complicated. It was a lot of information! We know that keeping everything only in spreadsheets can make it difficult to view the department globally.

Silas continued:

“We didn’t have any maintenance monitoring system; everything was done through spreadsheets. In 2019 we felt the need to computerize everything, so we surveyed some maintenance and fleet control systems, and the one that best met our expectations was Engeman®.”

Termov’s experience using Engeman®

After implementing the system, Termov executed all processes in stages as part of its migration to a computerized solution. By the company’s decision, everything was done gradually. See how the implementation process went at Termov, according to Silas:

“We have been implementing Engeman® in stages. The first thing we did was register assets, then we began printing Work Orders based on preventive maintenance control, and from a certain point, we started entering all W.O. Data Postings in Engeman®.

Even though we had a weak system, the spreadsheets, we still worked with them in parallel for a period because some employees had used them for 25 years, so it took us a while to leave them completely.

Since November 2022, we have been implementing Engeman® Mobile. In parallel, we are also implementing the inventory, as we were not working with real stock data in Engeman®. We are preparing to make the full migration so that next month, all inventory control will be done within Engeman®.”

Have you achieved results with Engeman®?

With the steps advancing and maintenance management being performed in Engeman®, Termov has already started its analyses through the system. Processes and interventions became more assertive and supported by more reliable data. See what Silas said:

“When you have the data, it becomes possible to analyze it and consequently plan much better. The preventive ones are more accurate, and the periodic ones are predefined. The software can predict cumulative interventions based on the hour meter with great accuracy.”

With data in the system, Termov was able to perform deeper analyses and have a real view of its maintenance sector. As a result, decisions became more data-driven, and interventions occurred at the right time, optimizing efficiency.

“After the implementation, things changed a lot here. Previously, we had people responsible for preparing spreadsheets and schedules. Today, Engeman® detects repetitions, rework, and recurring spare parts replacements. It greatly optimized our time and strategies because with data at hand, we have a complete view of each asset. When a machine has a problem, we know exactly what to do, renovations or even disposal.

Now we are working in the warehouse. Previously, I had to migrate all inbound information manually so the system could process write-offs. We are also adapting the posting of labor,” Silas added.

After implementing the software and migrating the data, Termov already sees excellent results because everything is computerized: saving time, paper, and storage space for documents. Silas shared an impressive result:

“We have so far achieved a 90% reduction in paper use!”

Fantastic!

The mobility that Termov has achieved

With everything registered in the system, Termov could access all data quickly. Since the company rents forklift equipment, it is common for an asset to require intervention at the customer’s location. Therefore, the employee performing the service needs access to the software to register Work Orders, Material Requisitions, or other information.

For situations like this, Termov uses Engeman® Mobile, which provides real-time data.

“We work with equipment rental, and with this rental, maintenance is performed on-site, under the customer’s contract. Engeman® Mobile has helped us a lot with Service Requests. On-site, the employee can report exactly what the problem is, including pictures, and we can make managerial decisions quickly. When materials are needed, everything is pre-planned. When no material is required, the service is authorized in just over 4 minutes,” said Silas.

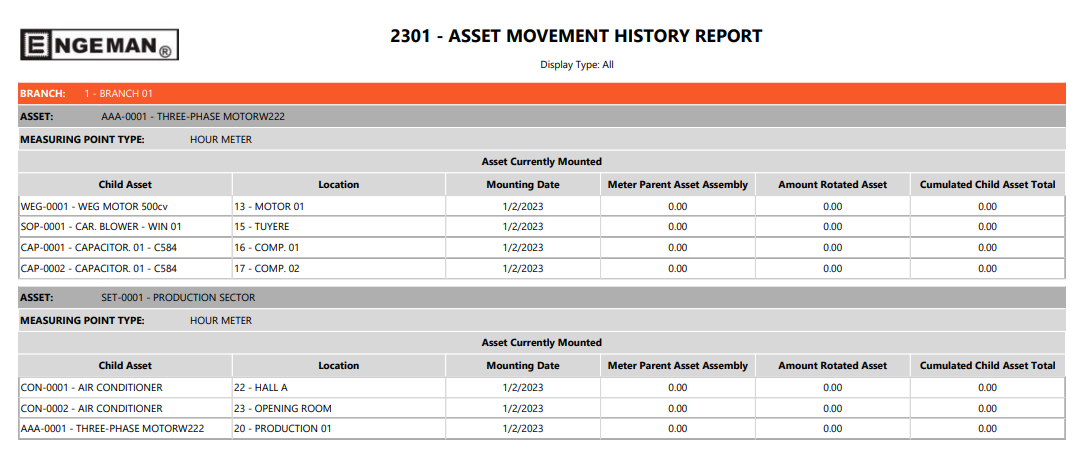

Maintenance histories in Engeman®

The wide variety of management reports available in Engeman® provides a real picture of the health of your maintenance sector. The correct control of indicators allows companies to work safely and increase reliability in their processes.

Engeman® software has more than 280 standard reports aimed at effective maintenance management. And if your company needs to analyze specific data, Engeman® has a specialized team that can customize any report to make your management as accurate as possible.

Below is just one example of a report that is very important when discussing your equipment’s history:

Conclusion

It is undeniable what technology can do for companies today. The increasing market demand requires businesses to produce more every day, and more production means more maintenance. We conclude that this sector cannot stop; it must work perfectly so the company can meet its demand.

For maintenance interventions to be executed correctly and for managers to have an accurate view of their department’s reality, they need data, equipment history, maintenance costs, and the entire record of the machines must be safeguarded.

As Silas mentioned, incorrect records can even lead to unnecessary maintenance. For efficient management, count on tools that provide a clear view of your data.

Engeman® is an expert software that helps thousands of clients in Brazil and abroad achieve excellent results with great ROI.

So, don’t waste time! Schedule a chat with our experts who will show you, in a free demo, the world of possibilities Engeman® can bring to your business.

To learn more about success cases like this one, visit our Success Cases page.