Contents

What is Mean Time Between Failure (MTBF)?

Mean Time Between Failures (MTBF) is the calculation that allows us to know the time elapsed between one failure and another. It’s basically the time when the machine will be available and in perfect working order for the company.

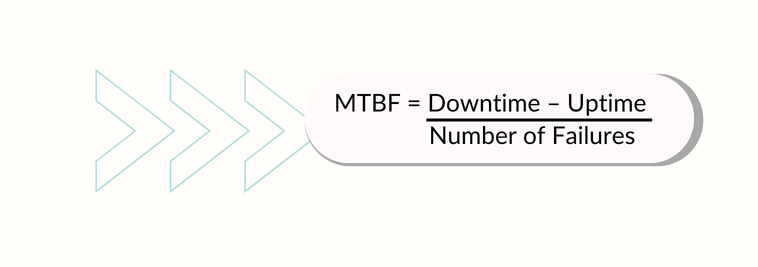

How to calculate MTBF?

To calculate Mean Time Between Failures, that is, this machine availability time, the MTBF formula below is used:

Where:

Downtime = Total of Availability Time. This variable corresponds to the ideal time that the machine should run if there is no downtime due to failure.

Uptime = Total of Maintenance Time. This variable corresponds to the time that the machine had to be stopped to make some repairs.

Number of Failures = This variable represents the number of times the machine had to stop for repairs.

How to apply MTBF?

Suppose that a certain machine must run for 36 hours. During this period, this machine was stopped for 2 hours to make some type of repair. During this time, it had to stop twice.

Let’s use the formula we learned:

MTBF = (Downtime – Uptime) / Number of Failures

MTBF= (36-2) /2

MTBF=34/2

MTBF=17 hours

Thus, we conclude that every 17 hours this equipment has the possibility of failing and having to stop for maintenance.

This indicator helps the maintenance management schedule actions aimed at optimizing operations to keep them as large as possible.

What is Mean Time To Repair (MTTR)?

MTTR, which means Mean Time To Repair, is the time it takes for the maintenance team to solve the failures of certain equipment. As a result, during this time the equipment will not be available for use.

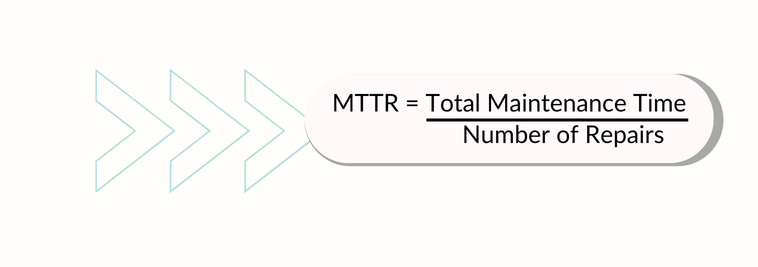

How to calculate MTTR?

To calculate the Mean Time To Repair, that is, the time of machine unavailability, the MTTR formula below is used:

Where:

Total Maintenance Time = This variable corresponds to the time that the machine had to be stopped to make some repairs.

Number of Repairs = This variable represents the number of times the machine had to stop for repairs.

Going back to our previous example, let’s now calculate the time spent repairing the machine in question:

MTTR = Total Maintenance Time / Number of repairs

MTTR= 2/2

MTBF=1 hour

How to apply MTTR?

Thus, we conclude that when this machine stops, it will be unavailable for repair for 1 hour.

The lower the MTTR value, the better, as this way the machine returns to production faster.

Concluding our example, every 17 hours the equipment in question may have a failure that needs maintenance, causing it to be unavailable for 1 hour.

Why is it important to use the MTBF and MTTR indicators?

With the correct records and calculations of these key performance indicators, the company can schedule all maintenance according to the histories and thus optimize production, since it knows on average how long it should stop to make repairs to its equipment.

In this way, it can schedule preventive maintenance (PM) and avoid unexpected downtime. It is also possible to understand the efficiency of your maintenance team through the time spent on repairs.

These indicators have been used for years in the industry and have been important allies in the planning of actions and maintenance optimization.

How does Engeman® use the MTBF and MTTR?

Well-measured key performance indicators give a very accurate diagnosis of how your company is doing. Engeman® software is used for the planning and control of maintenance and services. It does thorough work that involves data collection and analysis to achieve MTBF and MTTR.

Engeman® presents a solution for companies looking for data analysis to achieve incredible results to optimize their production.

Did you like our article on MTBF and MTTR? So don’t miss our blog updates and always stay well informed.

Want to know more about how Engeman® can help your company? Request a demo.