Every company that wants to be more competitive need to be attentive to fill parameters to control the quality of its processes. These parameters will direct the company actions that start on the factory floor until the executive positions. The results need to be measure and supervised to control long term plannings and investments.

For a successfully corporate management, the maintenance department must be managed carefully in order not to allow unforeseen events cause damage your business. In this way, some maintenance indicators have an important impact on the performance evaluation of your machinery. Machines available for production with high performance will bring financial benefits for business as well as contributing to increase the product’s quality.

So today we are talking about an important quality indicator, the OEE (Overall Equipment Effectiveness), that is used to monitor the machine’s development. This monitoring is essential in order to the maintenance management make assertive decisions, to bring more profitability to your business. But what is OEE? Why do you need to use it in your company to bring success to your business? Keep going in this article and know more about it.

What is the OEE?

Overall Equipment Effectiveness, represented by abbreviation OEE, it is a quality indicator that was presentation by Seiichi Nakajima, one of the creators of Total Productive Maintenance (TPM). The OEE used to check and track how is the equipment effectiveness during production.

With the OEE calculation and control, your company can have a better frequency’s management that the equipment will be available, how fast is your production and the number of products that does not provide any loss in production. It is possible to know all of this because the OEE consider three important indicators that are:

- Availability;

- Performance;

- Quality.

To understand better the OEE, first we need to know each indicator and how to calculate each one.

1. Availability

Availability is an important indicator that will determine whether certain equipment is available for work orders and requests or as if it is in operational state. So, the availability it is going to inform about all events that stop planned production.

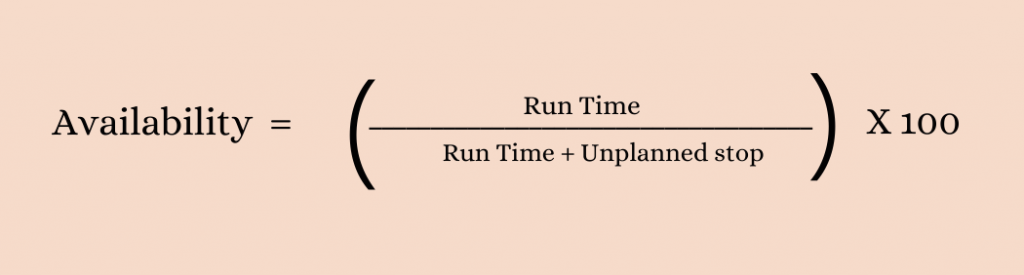

Availability is calculated with the time that the equipment works in comparison with the time it is available to use. Availability is calculated as the ratio of Run Time to Unplanned Production Time:

By World Class standard, the result value of the availability calculation must be greater than or equal to 90%.

2. Performance

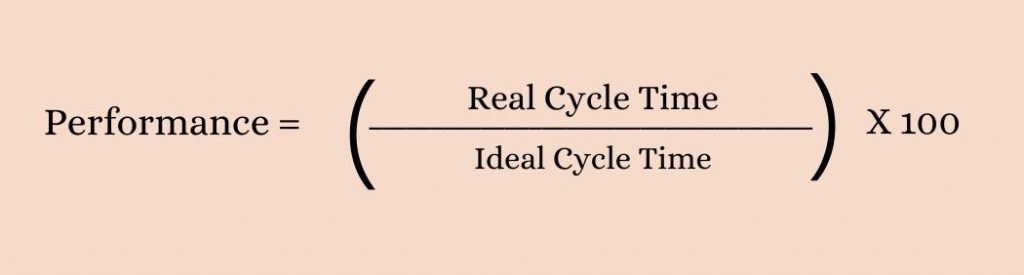

Performance analyzes how the production of certain equipment is going. This analysis is made through the speed at which the equipment should work and how effectively it works. This indicator will measure the performance of the equipment. It is calculated as:

The ideal cycle time is the time that the machine was programmed to run, and the real cycle time is the time that the machine was running. By World Class standard, the performance calculating result must be higher or equal than 95%.

3. Quality

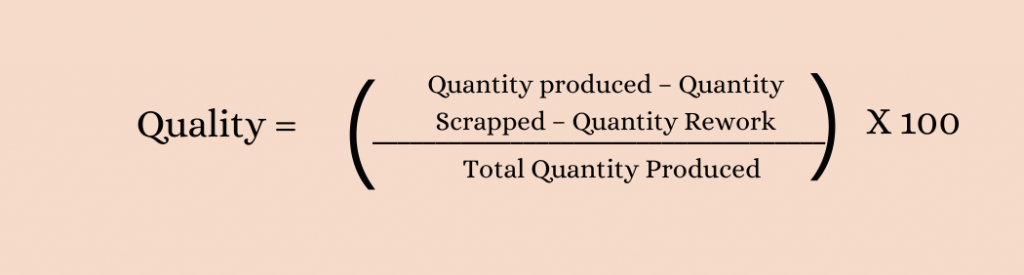

The performance indicator considers only machine production speed. But as we know, the product’s quality is a fundamental item to provide competitiveness to your business. In the quality indicator the company will define what are the product ‘s principle and from that will make a review about everting that is produced. Any material that leaves the specifications establish above is considered loss (scrap). For the calculation, we will use the formula:

By World Class standard, the result value of the quality calculation must be greater than or equal to 99.9%.

How to calculate OEE?

Well, as you know now what is each one of the three indicator that are involved in OOE, let’s go to the calculation itself.

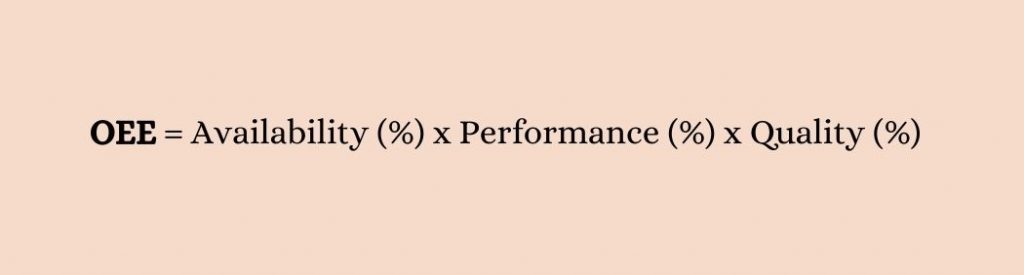

As mentioned earlier, the OEE considers availability, performance, and quality. The three quantities are directly proportional, so for the calculation, we will use the following formula:

By the World Class OEE, the result value of this calculation must be greater than or equal to 85%. Controlling the value of the OEE allows managers to know how efficient their company is and thus take effective action to improve their results.

Example of application of the OEE

To know the OEE, it is necessary to calculate each indicator separately and, at the end, multiply all the results. Let’s go to an example for you to understand better.

Suppose that a given machine works in 2 8-hours shifts. Therefore, its operation is 16 hours a day. During the working day, this machine of our example did not work all the time, because it was necessary to make some stops: 10 minutes to change operator and 20 minutes to solve a problem that has been presented. This machine is designed to produce 60 products per minute, but on this day, it produced only 54 per minute. Of these 54 products, 2 had to be redone and 1 was lost. With all the information about the production of this machine, let’s go to the calculations!

We will start here by calculating availability.

- Set time for operation: 960 minutes

- Total downtime: 30 minutes (10+20)

Availability = Time in production / Time in production + Stops

Availability = 960 / 960 + 30

Availability = 960 / 990

Availability = 0.9696 X 100

Availability = 96.96%

Now we move on to the next step which is the performance calculation of this machine. As our calculation will finish by quantity of products, we will change in the formula what is being analyzed.

- Production in 1 real minute: 54

- Production in 1 minute ideal: 60

Performance = Real production / Ideal production

Performance = 54 / 60

Performance = 0.9 X 100

Performance = 90%

Next, we will calculate the quality of the products produced by this machine.

- Quantity produced: 54

- Quantity scrapped: 1

- Quantity of rework: 2

Quality = Quantity produced – Quantity scrapped: – Quantity rework / Quantity produced

Quality = 54 – 1 – 2 / 54

Quality = 51 / 54

Quality = 0.944 X 100

Quality = 94.4%

Once the three indicators have been calculated, we can now go to the Calculation of the OEE:

OEE = Availability (%) x Performance (%) X Quality (%)

OEE = 96,96% X 90% X 94,4%

OEE = 82,37%

After the calculations performed and with the indexes in hand, the manager has a decision based on factual information to find efficient ways to increase your OEE indexes, bringing benefits to your company. But what are the benefits of keeping the OEE high by World Class standard? We will answer next!

The OEE benefits

Using OEE calculations and keeping your percentage within the right standards, your company will be more competitive. Your corporation will have benefits such as:

- Optimization of maintenance costs;

- Better product quality;

- Assertive planning;

- Time optimization;

- Strategic use of machines;

- Higher productivity;

- Increased profitability by increasing equipment production;

- Improve the productive capacity of the company, among others.

The OEE is an important index for an efficient administration of any company. Knowing it is possible to understand how the efficiency of the equipment acts in production. An OEE that is low may indicate that there is a lot of downtime and considerable production losses.

OEE and TPM

The OEE is a concept that emerged in the TPM (Total Productive Maintenance) methodology. The central goal of the two programs is zero fault and defect. The actions of the third and fourth pillars of TPM are important because they have a direct influence on the OEE. In The Specific Improvement, for example, actions are conducted with the objective of eliminating the six large losses that have a direct influence on the OEE. These six major losses are:

- Break;

- Setup;

- Idle time;

- Low speed;

- Defects in the process and rework;

- Start-up.

Use of software for OEE control

The OEE is one of the main indicators for measuring efficiency in the industry. Doing your control properly brings enormous benefits to any company. With the considerable number of equipment, controlling the entire history in spreadsheets makes the work of managers difficult, besides compromising data reliability. Therefore, management software is the best solution for data to be used for the correct calculation of the OEE.

Using software that has a mobile module, for example, allows all information to be posted in real time, all stops, work orders and equipment performance data so that actions are taken more quickly.

With Industry 4.0, those organizations that do not suit technology will see their competitors move ahead, managing to increase their OEE indexes and thus being more competitive in the market. CMMS software allows critical data to be gathered in one place and thus make in-sight management more efficient.

Did you know that Engeman® has several tools and reports that facilitate your maintenance management and help your business increase OEE? Request a presentation with our experts and see all the possibilities that our solution has for your company!