Specific Date Planning

This scheduling process operates similarly to the periodic but with specific dates, such as:

- Maintenance is performed every 1st of each month;

- Maintenance is performed every December 25 of each year;

- Maintenance is performed only from Monday to Friday of each week.

In this format, Engeman® allows the consecutive issue of more than one W.O. referring to the same plan and the same schedule within a period established by the user. Example: If the schedule is for every first day of each month and the requested period is one year, then at least 12 W.O. will be issued to the asset.

Once the parameters have been determined, work orders can be calculated and issued. The closing of these automatically reschedules the next performing date, with no need to perform new startups.

Even if a work order is placed outside the scheduled date, Engeman® will keep the original schedule dates so as not to harm other existing schedules.

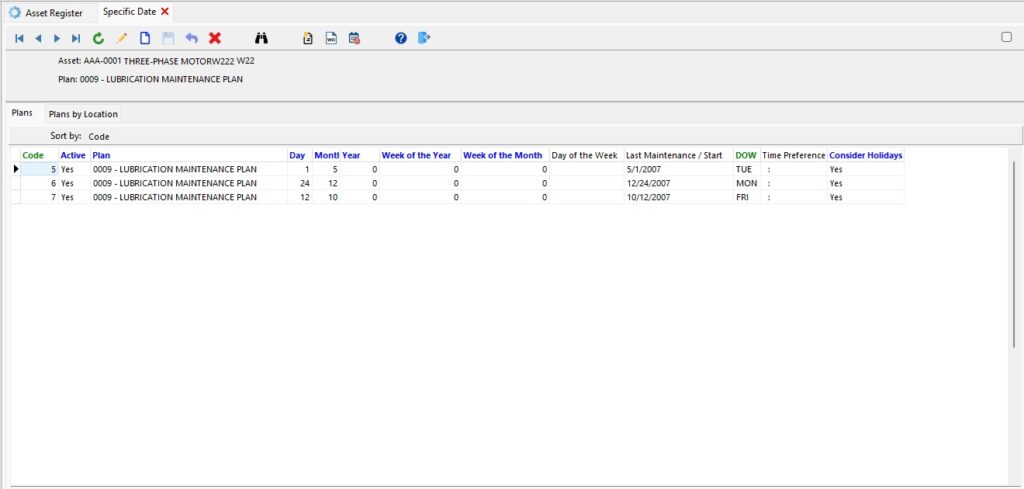

The Specific Date Schedule at Engeman®

To schedule a plan with this type of operation, we need to pay attention to some points within Engeman®.

When accessing, within the maintenance plan, the option by Specific Date, the following information is displayed:

- Schedule status: active or not – if it is active, the system calculates the W.O. for the schedule.

- Asset: equipment to which the maintenance plan will be applied. If there is more than one asset in the same location, one or more W.O.s will be generated for each of them.

- Specific date differentiated into day – month – year – day of the week: To specify a repeating date, such as day and month for any year, leave the year field with a value of zero – ditto for the day of the week.

- Week of the Year: Enter the number of the week of the year for maintenance and the day of the week (SUN to SAT). The first week of the year, by definition, is the week that contains the most days in January. In other words, the first week of the year is the one that contains January 4th. The year can have 52 or 53 weeks, depending on the distribution of the days. Therefore, avoid registering maintenance that appears only in week 53, as this occurrence is rare, and maintenance will not be performed annually. To apply maintenance to a particular year only, enter the year for it.

- Week of Month: Enter the week number within a month (1 to 6) and the day of the week (SUN to SAT) of the maintenance. Example: determining the week of the month = 1 and the day of the week = WED, the maintenance will be performed on the entire first Wednesday of a month. (Even if the first day of the month falls on a Friday, the first Wednesday will be the following week, that is, in week two of the month.). If you want to apply for this maintenance for only a certain year, enter the desired year.

IMPORTANT TIP: To ensure that the W.O. is always generated on any day of the last week of the month, enter the value “6” in the “Week of the Month” field. If the month is only 4 or 5 weeks old, the W.O. will be generated in the last week anyway.

- Last maintenance date: date from which the plan will be started.

- DOW (Day of the Week): This field is informational only. Indicates the day of the week on which the last maintenance occurred.

Conclusion

With this information, we can create much more assertive maintenance schedules, which will not only have the calendar day as a parameter.

Creating a schedule of a plan by a Specific Date does not invalidate another periodic schedule made for the same maintenance plan and on the same asset, but it can generate problems of duplication of services if we are not attentive.

Engeman® can handle this automatically in a feature called Concurrent Plans. We will talk about this subject in more detail in the next article, still about a type of maintenance that can often be understood as time-based but which already introduces a new type of scheduling: Condition-Based Maintenance (CBM) – this scheduling is Cumulative Scheduling.

Also read the first article of the series: Maintenance Scheduling at Engeman®: 1st – Periodic – Time-Based Maintenance (TBM)